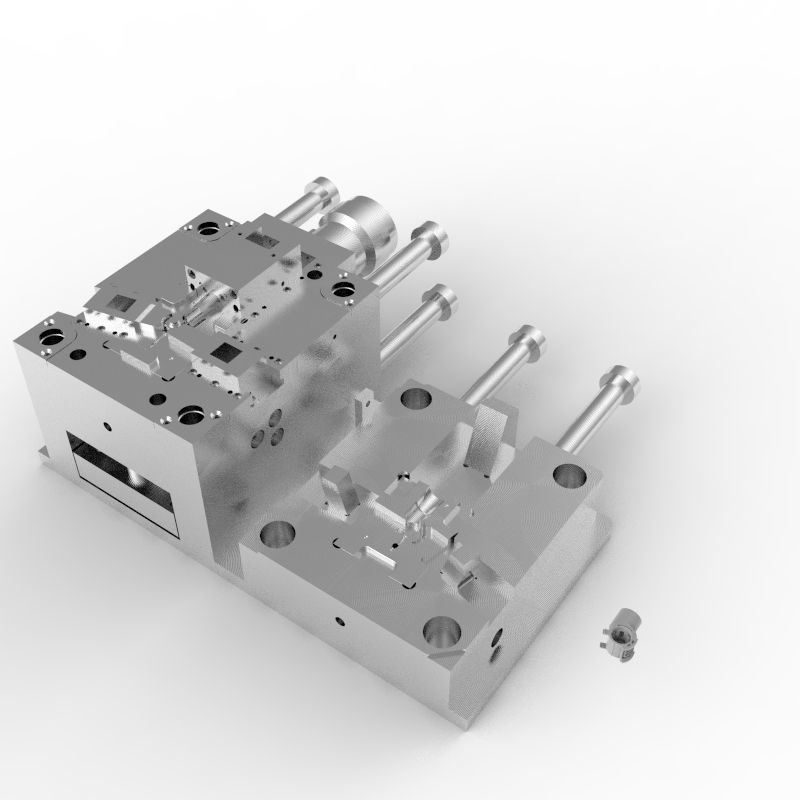

Household Appliance Mould Main Make Air Conditioning Mold

Manufacturing Technique:injection plastic

Mould Core:S136

Mould Base :45# steel

Cavity:1

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

Household appliance moulds are a type of mould used to create air conditioning moulds. These moulds are used to shape and form air conditioning systems that are used in homes and businesses. The moulds are made from a variety of materials, including plastic, metal, and rubber. The moulds are designed to be durable and to withstand the heat and pressure of the air conditioning system.

The process of creating a mould for an air conditioning system begins with the design of the system. Engineers will create a design that will be used to create the mould. The design must be precise and accurate to ensure that the mould will fit the system correctly. Once the design is complete, the mould is created using the materials specified in the design.

The mould is then placed into a mould machine, where it is heated and pressurized. This process ensures that the mould is strong and able to withstand the pressure and heat of the air conditioning system. Once the mould is complete, it is placed into an oven to cool and dry.Once the mould is dry, it is ready to be used to create the air conditioning system. The mould is used to create the various parts of the system, such as the fan, compressor, and condenser. The parts are then assembled to create the air conditioning system.

Product Specification:

| Household Appliance Mould Main Make Air Conditioning Mold | |||||||

|

factory |

mould name |

mold cavity |

mold core |

mold base |

mold delivery time |

shot(times) |

circle time(second) |

|

fengjin |

air conditioning mold |

1 |

S136 |

45# |

40days |

300000 |

95 |

Overall, the use of moulds to create air conditioning systems is an important process. The moulds are strong and durable and are designed to last for many years. They are also easy to maintain and install, ensuring that the air conditioning system will remain in good condition for many years.

We can custom other plastic mould we require,welcom to contact us for details.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

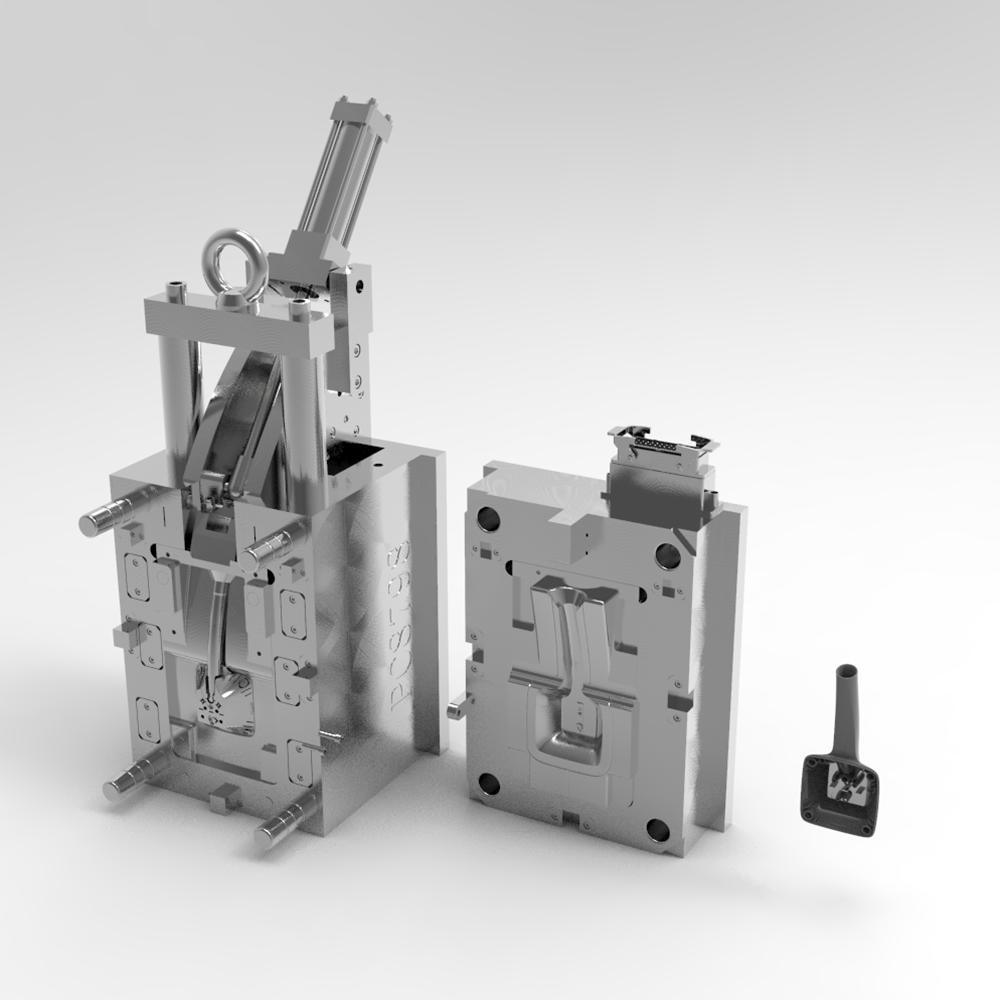

Plastic Injection Mould Manufacturing For Hand Shower

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order