Plastic Injection Company Design Die For Electrical Parts

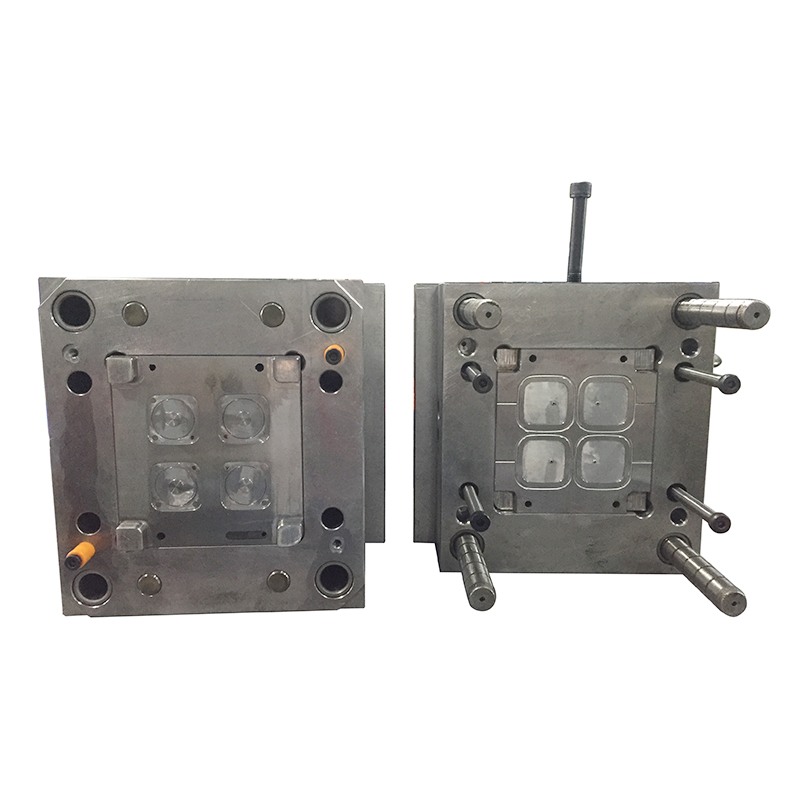

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:4

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

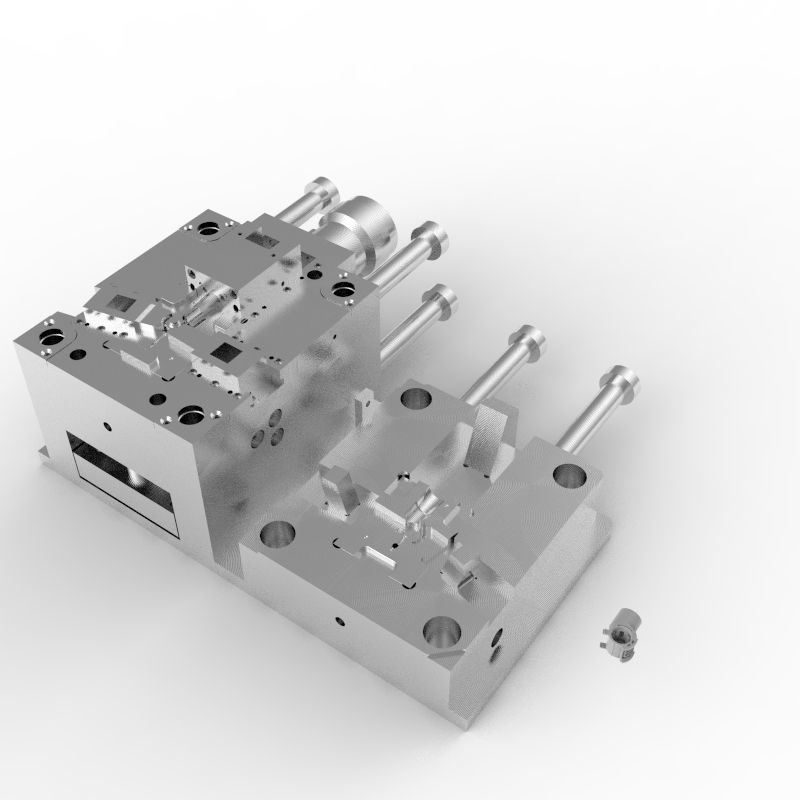

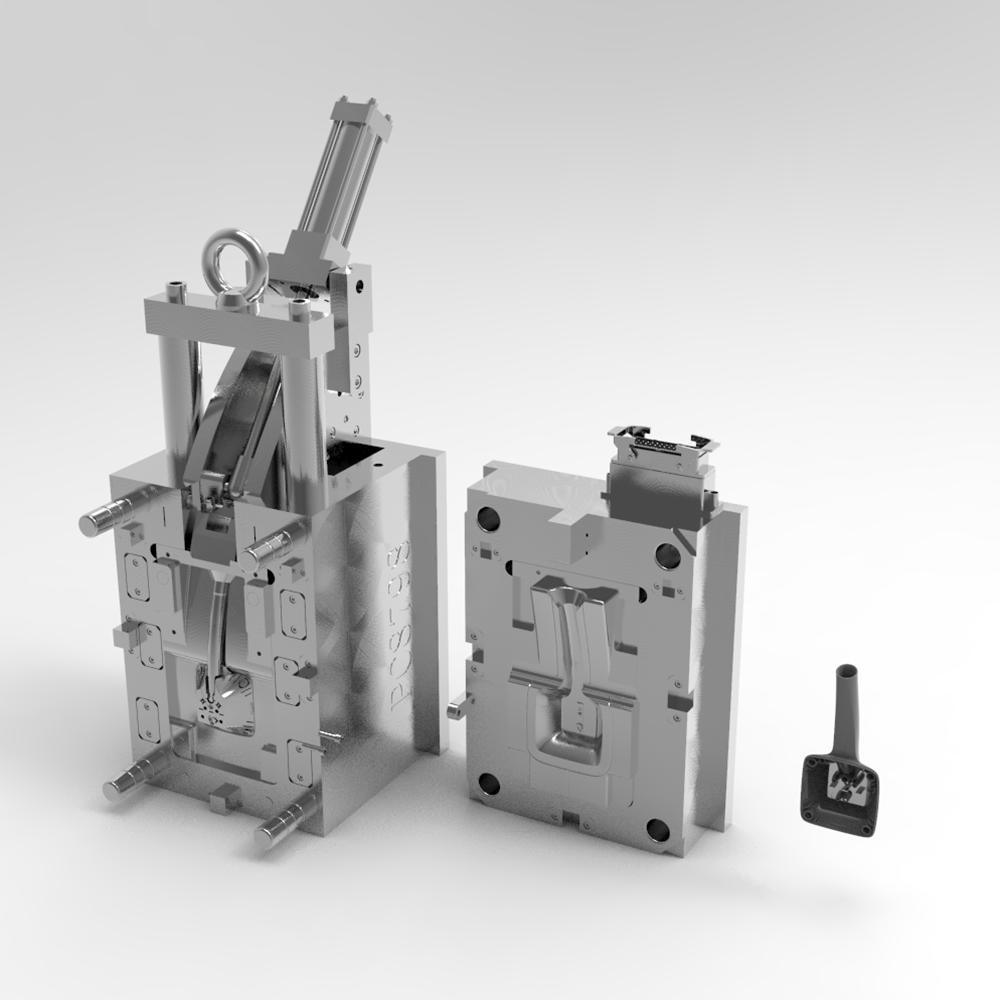

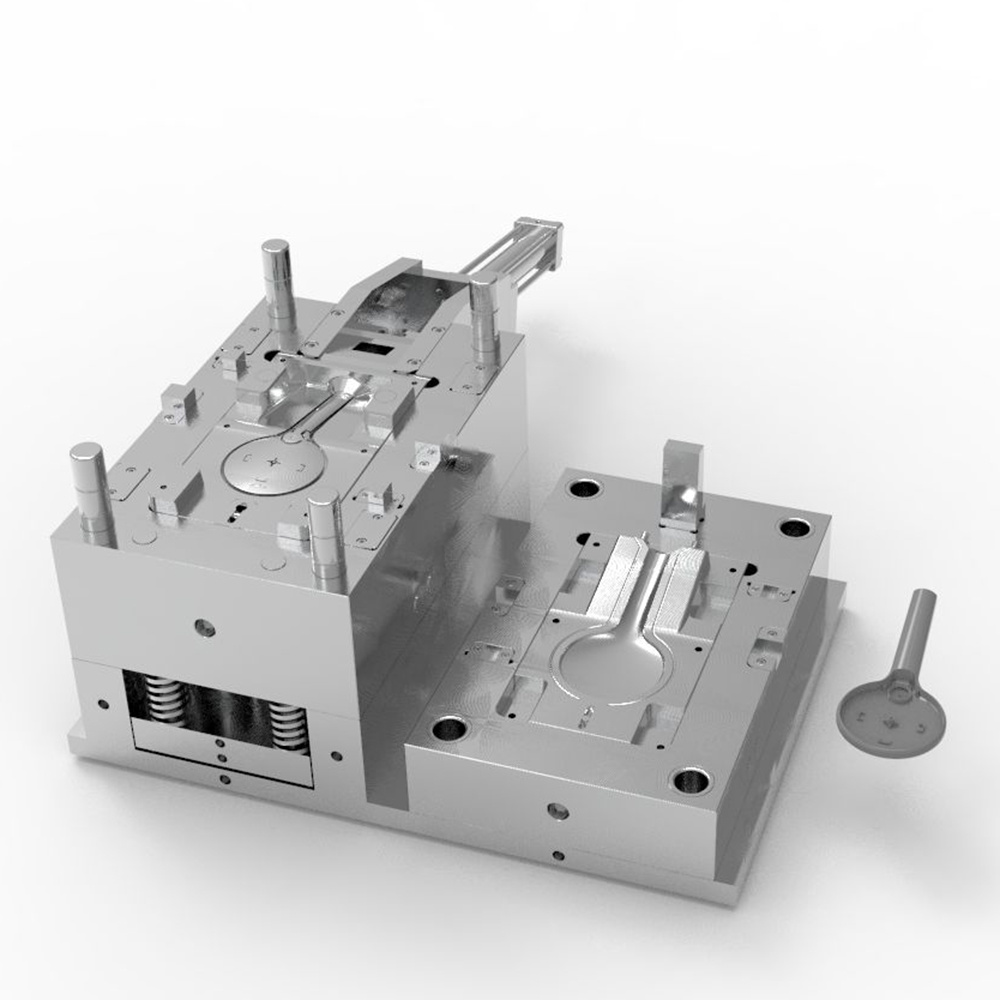

Injection molding is a precise and accurate process used to create custom-designed parts for a variety of products. Designing a die for electrical parts requires careful consideration of the material properties, size, shape, and other features of the part. The die must be designed with the right size and shape to ensure the part fits properly in the mold. In addition, the die must be designed with the right materials to ensure the part is strong and durable. The prototype of the die must be created and approved before the die is produced

Plastic injection electrical parts moulding is a process used to create components with intricate shapes and designs. It involves injecting molten plastic into a mould and allowing it to cool and harden. This process is used to create a variety of electrical components, from circuit boards to connectors and switches. The process of plastic injection moulding is highly precise and requires a high level of skill and experience to produce quality components.

Product Specification:

| Plastic Injection Company Design Die For Electrical Parts | |||||||

|

factory |

mould name |

mold cavity |

mold core |

mold base |

mold delivery time |

shot(times) |

circle time(second) |

|

fengjin |

electrical parts plastic mould |

4 |

S136 |

45# |

40days |

300000 |

45 |

The process begins by designing a mould that will be used to create the desired electrical parts. This mould is typically made of metal and is designed to match the exact specifications of the parts being created. The mould is then filled with molten plastic which is injected into the mould using a hydraulic or mechanical press. The plastic is then allowed to cool and harden before being removed from the mould.

Once the parts have been removed from the mould, they are usually machined to create the exact shape and dimensions desired. This process can involve drilling, cutting, and grinding the parts to ensure that they meet the exact specifications. The parts may also be coated with a protective coating to protect them from corrosion and wear

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Plastic Injection Mould Manufacturing For Hand Shower

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate