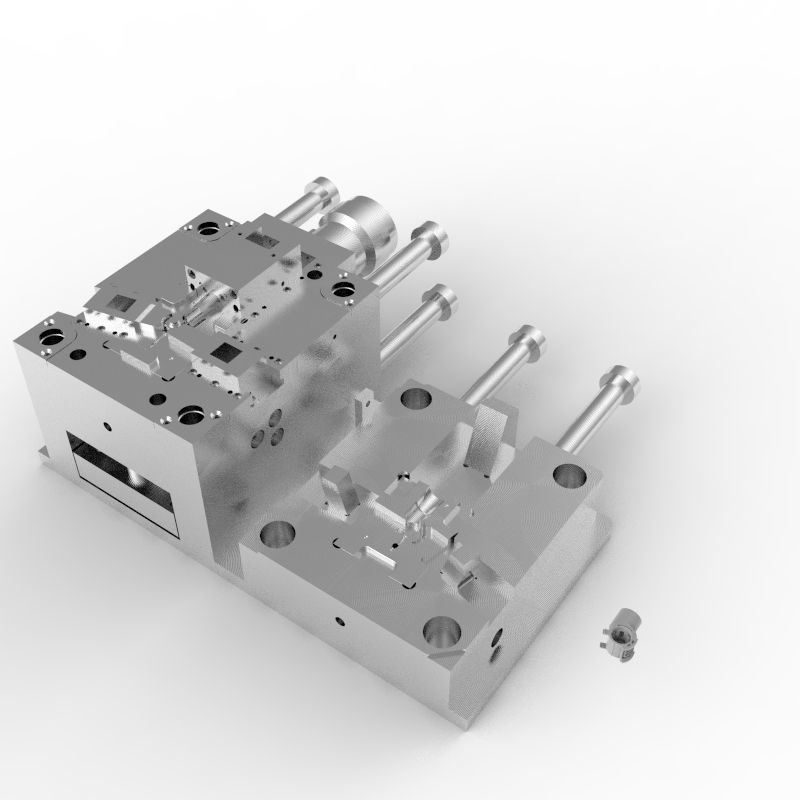

Injection Manufacturer For Socket Mould

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:2

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

Socket mould injection manufacturers use a variety of materials, including polypropylene, polycarbonate, and ABS, to produce their parts. The injection moulding process involves melting the plastic material, injecting it into a mould, and then cooling it to form the desired shape. Once the part is formed, the mould can then be used to produce multiple copies of the same part in a short amount of time.

Injection moulding is a cost-effective way to produce parts with high precision and accuracy. It also allows for a wide range of shapes and sizes, allowing for more creative designs. Socket mould injection manufacturers can also produce parts with a variety of textures and colors.

Socket mould injection manufacturers must also be aware of the environmental impact of their production process. They must take into account the amount of energy and resources used in the production process, as well as the disposal of any waste materials.

Product Specification:

|

Injection Manufacturer For Socket Mould |

|||||||

|

factory |

mould name |

mold cavity |

mold core |

mold base |

mold delivery time |

shot(times) |

circle time(second) |

|

fengjin |

injection socket mould |

2 |

S136 |

45# |

40days |

300000 |

65 |

Socket mould injection manufacturers must also be aware of the latest trends and technologies in the injection moulding industry. This includes the use of 3D printing, which is becoming increasingly popular in the industry. 3D printing is a cost-effective way to produce parts with intricate details, as well as parts with complex shapes and sizes.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m ,we can offer just production if your mould is done

Beside Injection Manufacturer For Socket Mould,we can custom other plastic parts mould,welcome to contact us any time .

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order