Injection Molding Manufacturers For Bathroom Faucet Fogger

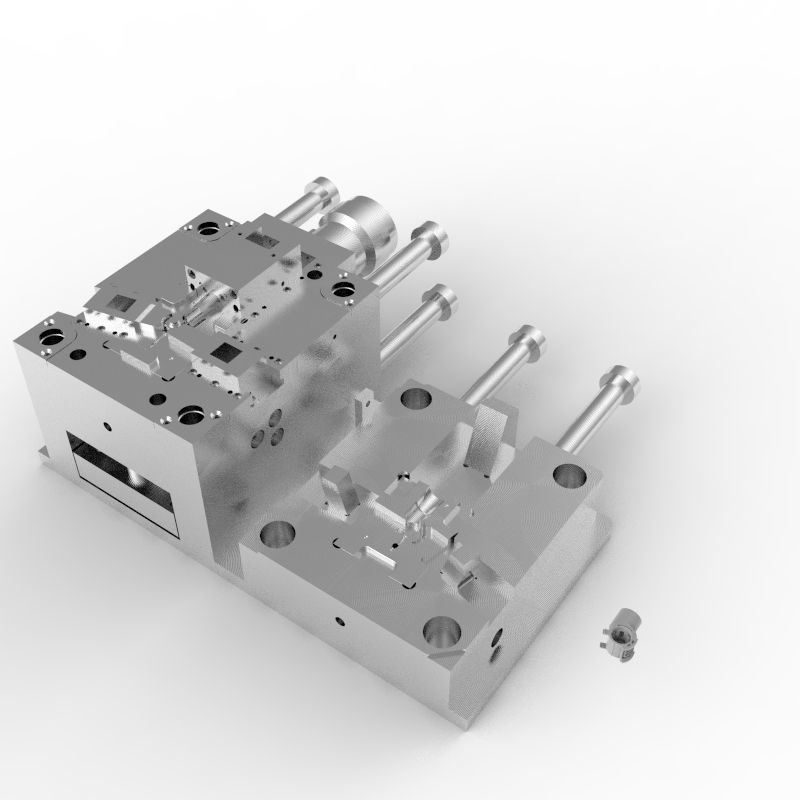

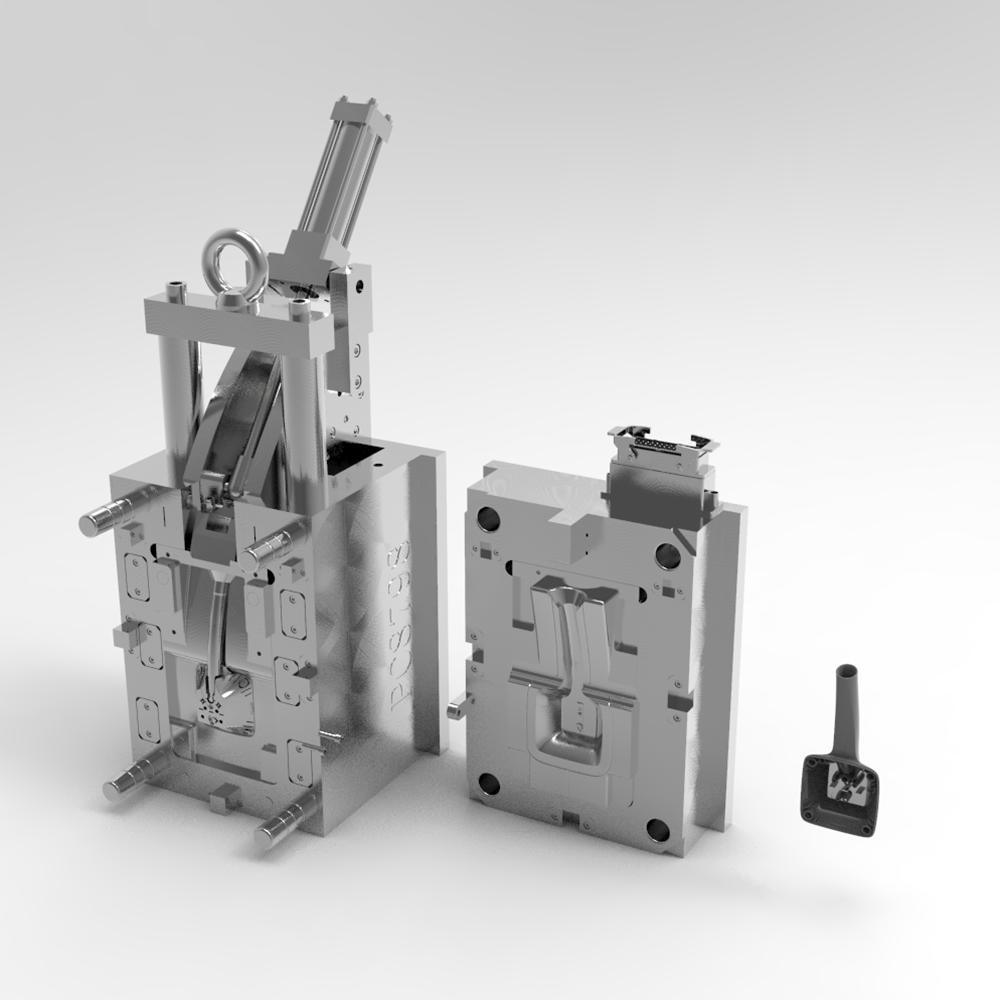

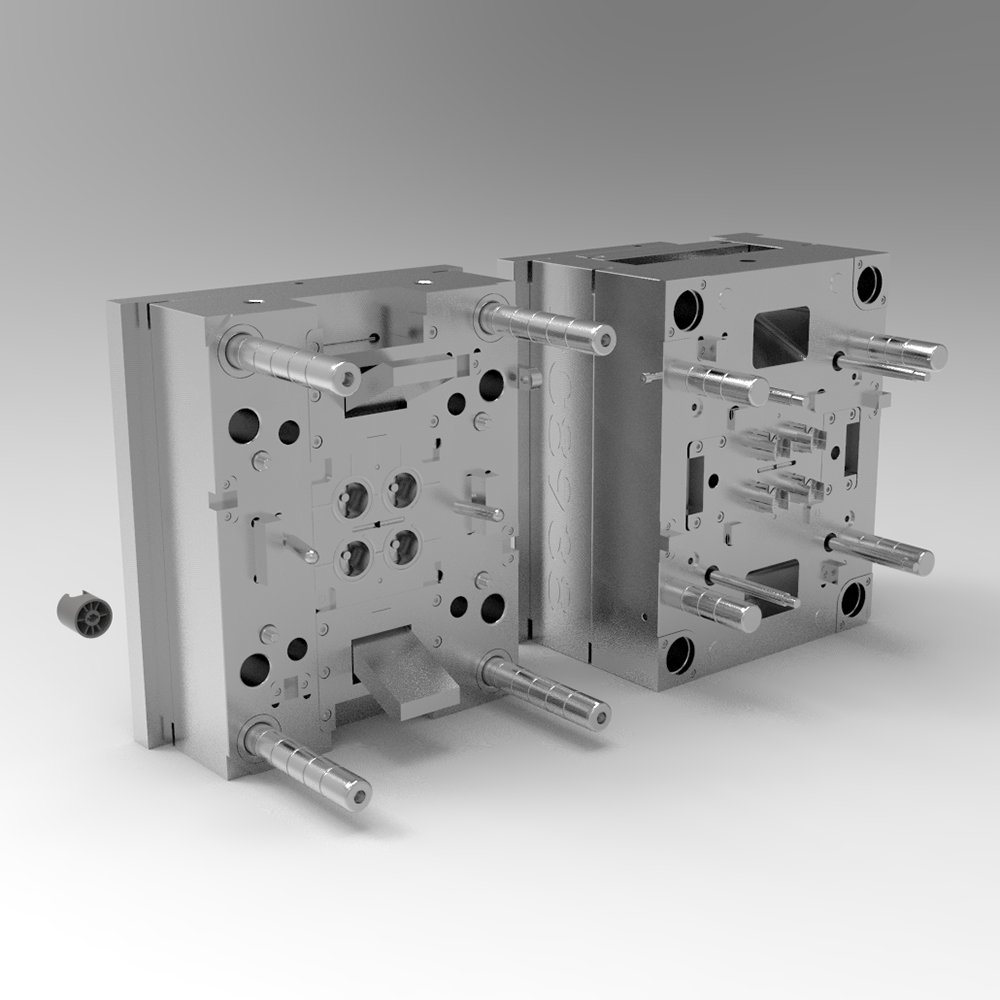

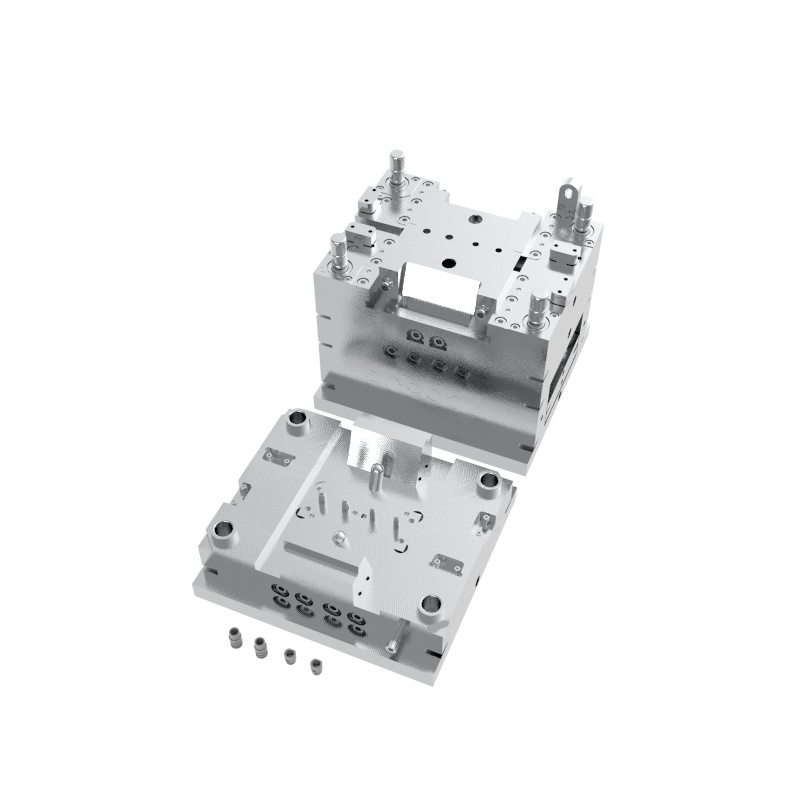

Manufacturing Technique:injection plastic mould

Mould Core:S136

Mould Base :45# steel

Cavity:2

Factory Location:Xiamen,China

Supply Capacity: 60sets/month

Injection molding is one of the most popular methods used to manufacture bathroom faucet foggers. This process involves injecting molten plastic into a mold in order to create a desired shape. The injection molding process is relatively simple and cost-effective, making it a popular choice for many manufacturers.

Handshower plastic injection mold finish by precise CNC.Have single function and multifunction as customer require.Can design and make some change on products according to customer's requirement.

Product Specification:

|

Injection Molding Manufacturers For Bathroom Faucet Fogger |

|||||||

|

factory |

mould name |

mold cavity |

mold core |

mold base |

mold delivery time |

shot(times) |

circle time(second) |

|

fengjin |

barhroom faucet fogger mould |

2 |

S136 |

45# |

45days |

380000 |

55 |

Injection molding is the most common method used to produce bathroom faucet foggers. The process begins with the selection of a mold and the preparation of the molding material. The molding material is heated to a temperature that is high enough to melt it and then injected into the mold. The molten plastic then cools and hardens, forming the desired shape.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

The injection molding process is highly efficient and can produce large quantities of bathroom faucet foggers in a short amount of time. This makes it an ideal choice for manufacturers who need to produce large numbers of products quickly and cost-effectively. Additionally, the injection molding process is relatively simple, allowing manufacturers to quickly and easily create complex shapes and designs.

Injection molding is also a very precise process, which allows manufacturers to produce bathroom faucet foggers with a high degree of accuracy. The process is highly versatile and can be used to create a wide range of shapes and sizes. This makes it ideal for creating custom products for specific applications.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate

Injection molding is a cost-effective method of manufacturing bathroom faucet foggers. The process is relatively simple and can be completed in a short amount of time. Additionally, the injection molding process is highly precise and can create complex shapes and designs. For these reasons, many manufacturers choose to use injection molding to produce bathroom faucet foggers and series products.Welcome to send inquries.