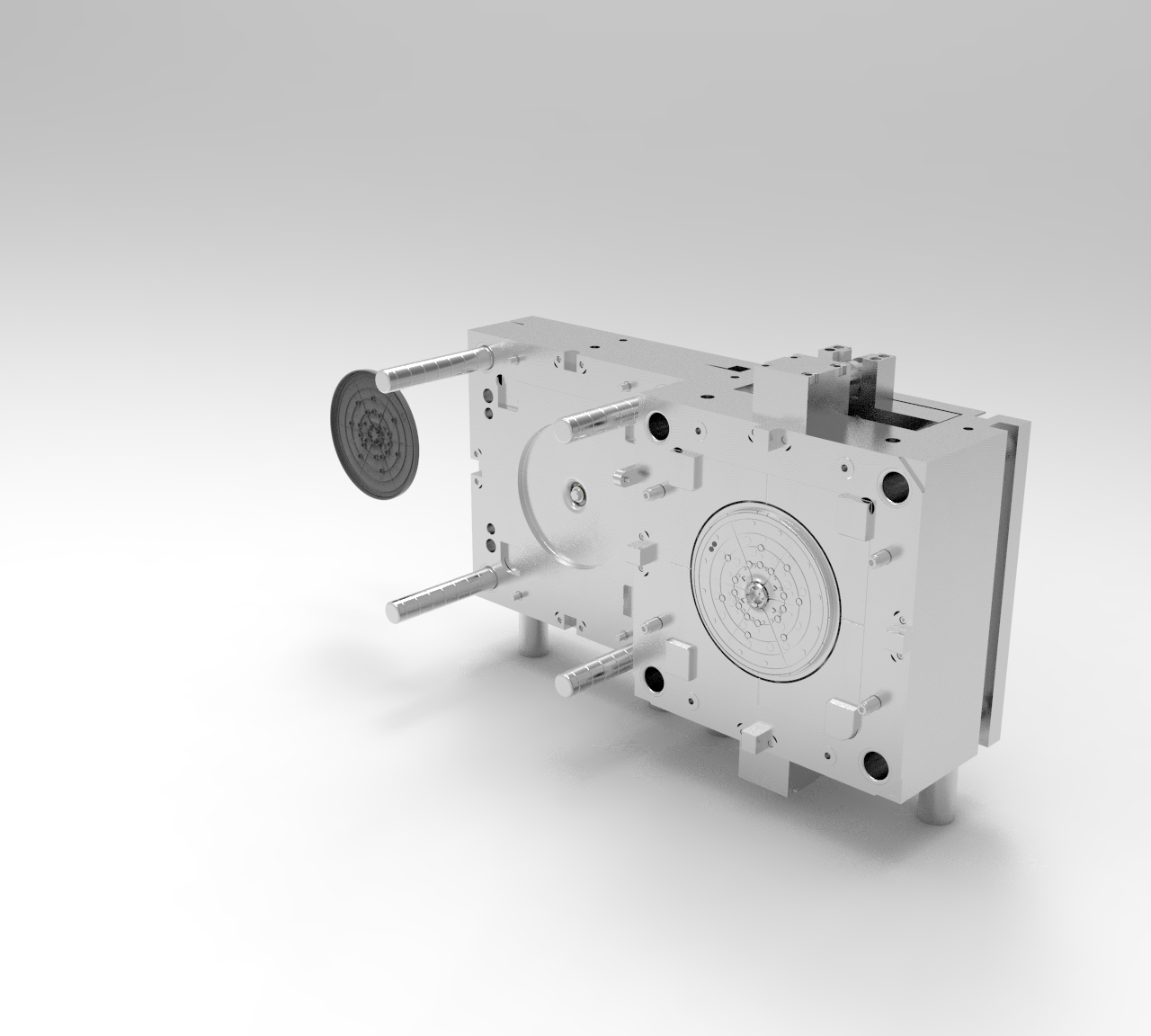

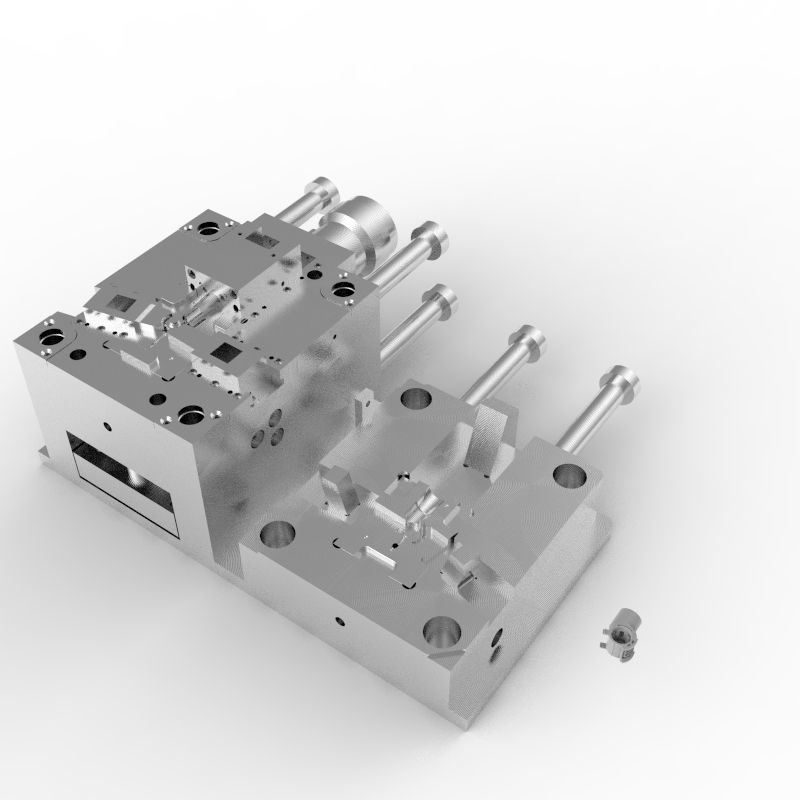

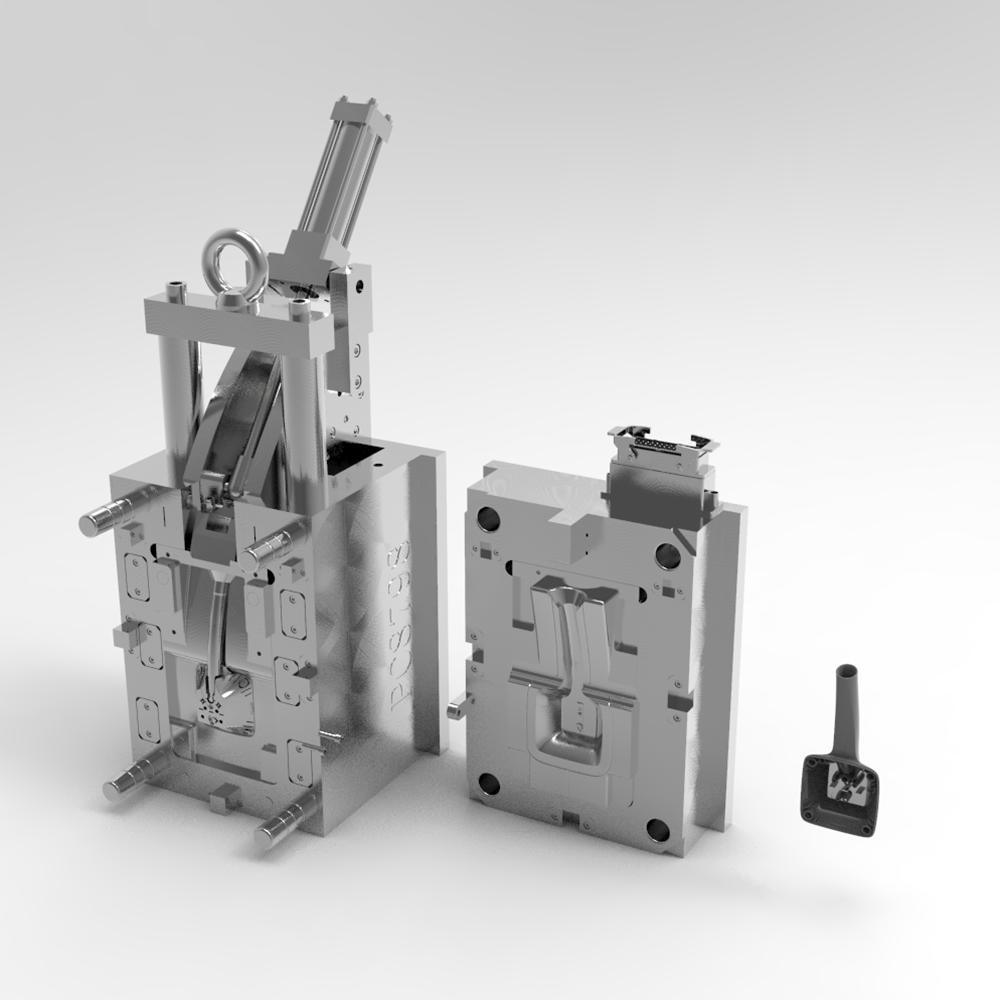

Plastic Injection Maker Make Top shower and Hand Shower Mold

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:1

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

Plastic injection molding is a versatile and cost-effective process for making top shower and hand shower molds. The process is fast and efficient, allowing for a wide range of shapes and sizes to be created with high precision and accuracy. The process is also relatively easy to learn and can be used by a variety of industries. Whether you need to create a top shower or hand shower mold, plastic injection molding is the perfect solution

Product Specification:

|

Plastic Injection Maker Make Top shower and Hand Shower Mold |

|||||||

|

factory |

mould name |

mold cavity |

mold core |

mold base |

mold delivery time |

shot(times) |

circle time(second) |

|

fengjin |

top shower mold |

1 |

S136 |

45# |

40days |

300000 |

95 |

And we can offer some related products mould like soab case on shower stand and other plastic parts like slidding cover mould,friction pad mould,fasten nut mould,marbles mould,non-slip mat mould,decoration ring moulding,decoration cover of suspension base mold,sprayer body injection mould and so on. The cavity can decide according to customer's production capacity.Some more mould pics we make for your refer

Once the mold is machined, the plastic is injected into the mold. This is done using a plastic injection molding machine, which uses a metal plunger to force the molten plastic into the mold. The plastic is then cooled and solidified, forming the desired shape.The next step is to finish the part. This involves trimming, grinding, and polishing the part to achieve the desired finish. The plastic injection molding process is often used to create intricate parts with high precision and accuracy.The final step is to inspect the part for any imperfections. This is done using a variety of methods, such as visual inspection, dimensional inspection, and non-destructive testing. Once the part has been inspected, it is ready for use.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Plastic Injection Mould Manufacturing For Hand Shower

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order