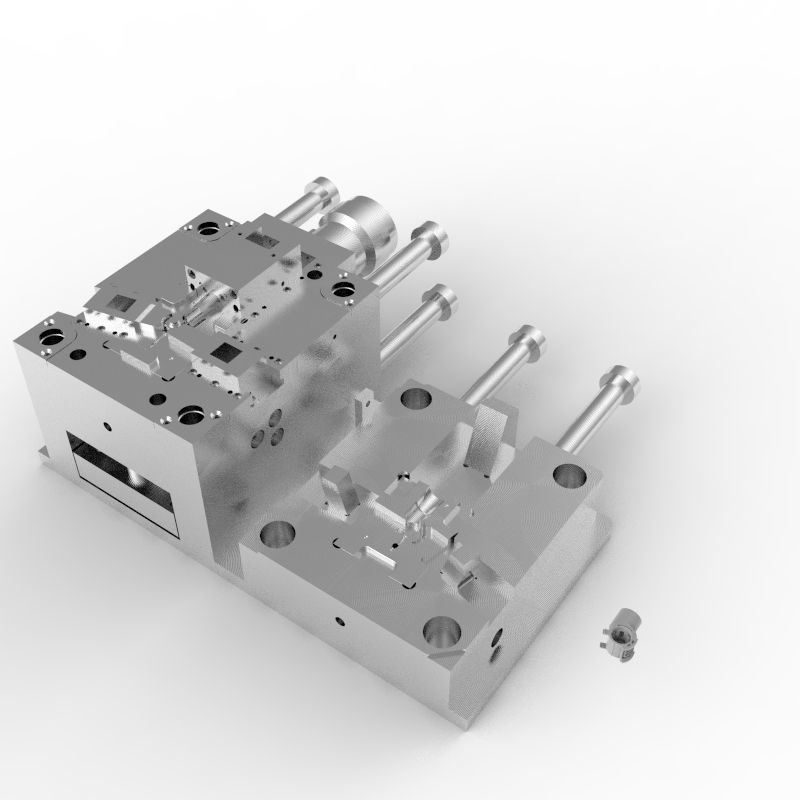

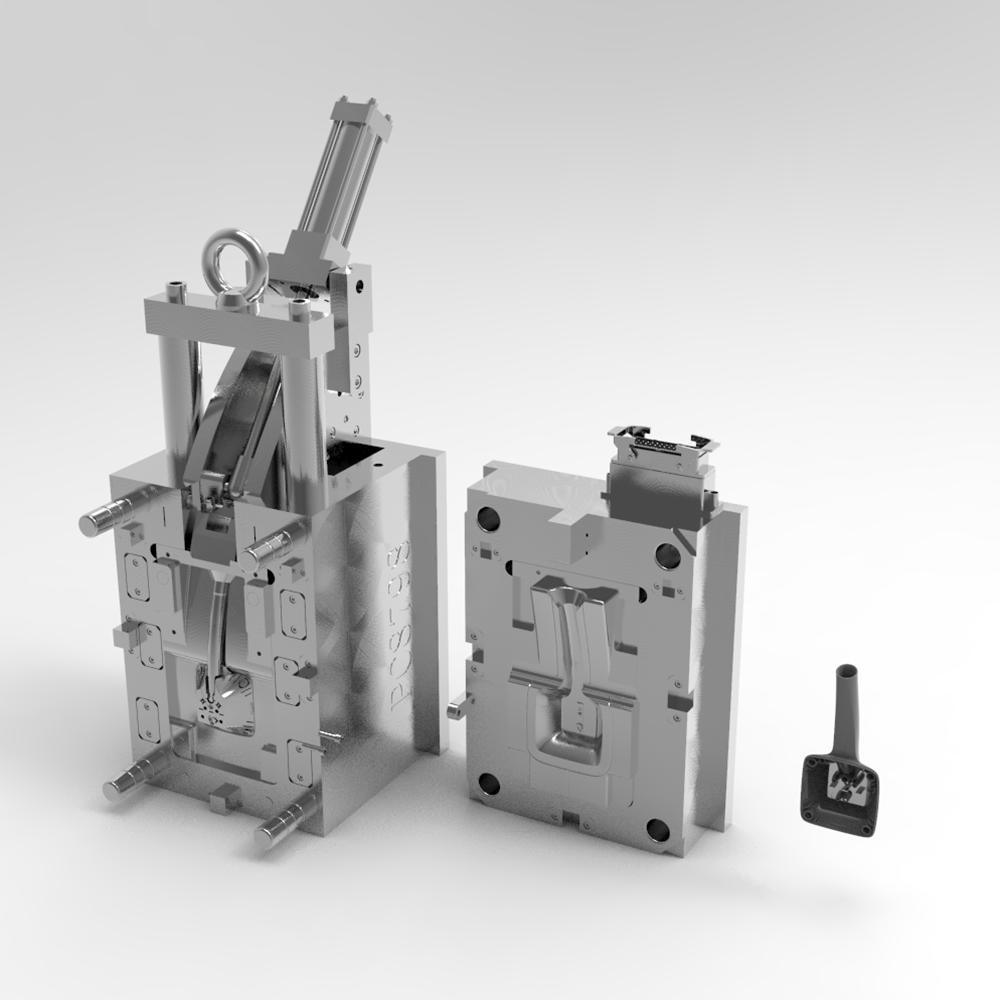

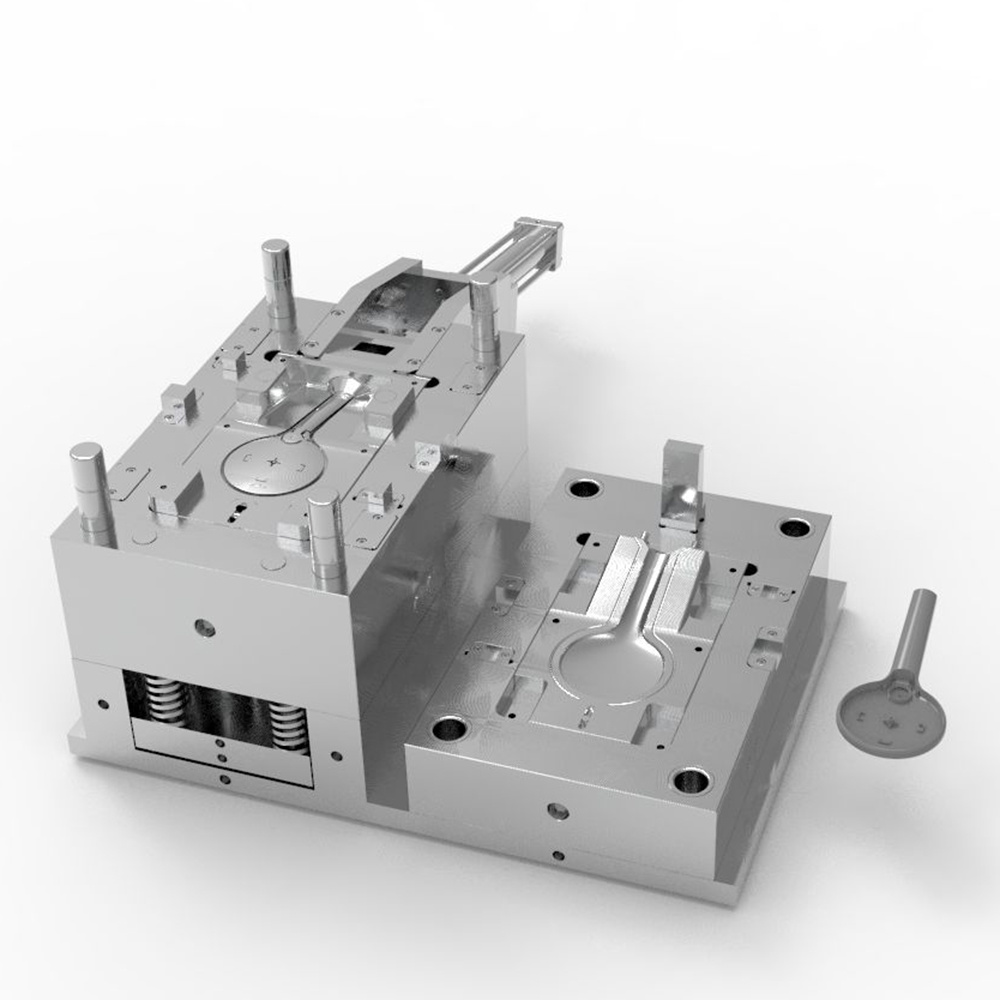

Faucet Filter Net Body Aerator Plastic Injection Parts Mold

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:2

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

Faucet Filter Net Body Aerator Plastic Injection Parts Mold is a highly specialized and intricate process that requires precision and expertise. The process involves injecting molten plastic into a mold, which is then cooled to create the desired shape. The mold is then used to create the parts that make up the faucet filter net body aerator. The parts are then assembled into the final product. The process is complex and requires a great deal of skill and experience to ensure the highest quality of product.

Product Specification:

| Faucet Filter Net Body Aerator Plastic Injection Parts Mold | |||||||

|

factory |

mould name |

mold cavity |

mold core |

mold base |

mold delivery time |

shot(times) |

circle time(second) |

|

fengjin |

faucet filter plastic mold |

2 |

S136 |

45# |

40days |

300000 |

40 |

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate