Customized Plastic Injection Mould For Top Shower /Hand Shower

Manufacturing Technique:plastic injection

Runner:Cold

Mould Core:S136

Mould Base :C50

Cavity:1

Factory Location:Xiamen,China

Supply Capacity: 55-65sets/month

Kep Words:plastic injection moulding

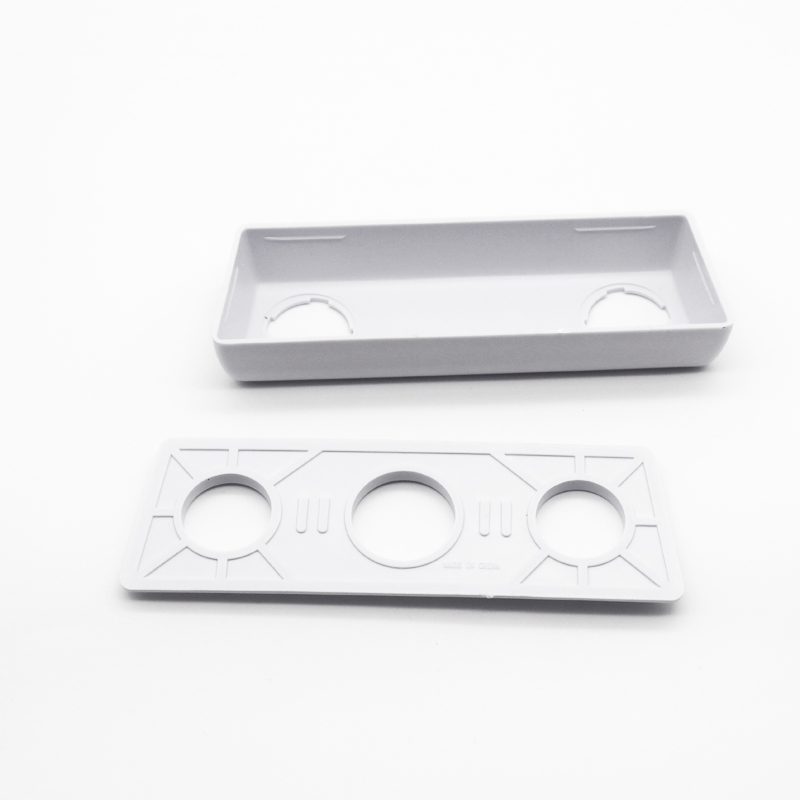

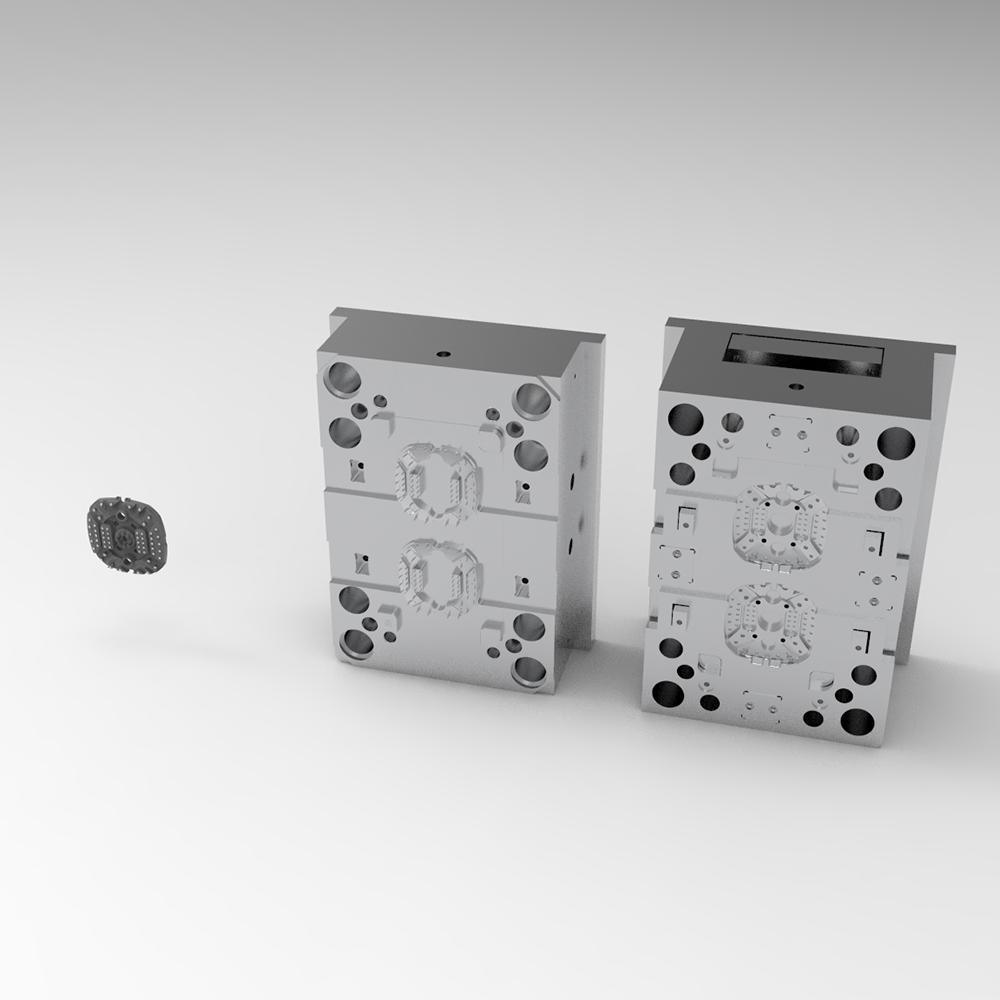

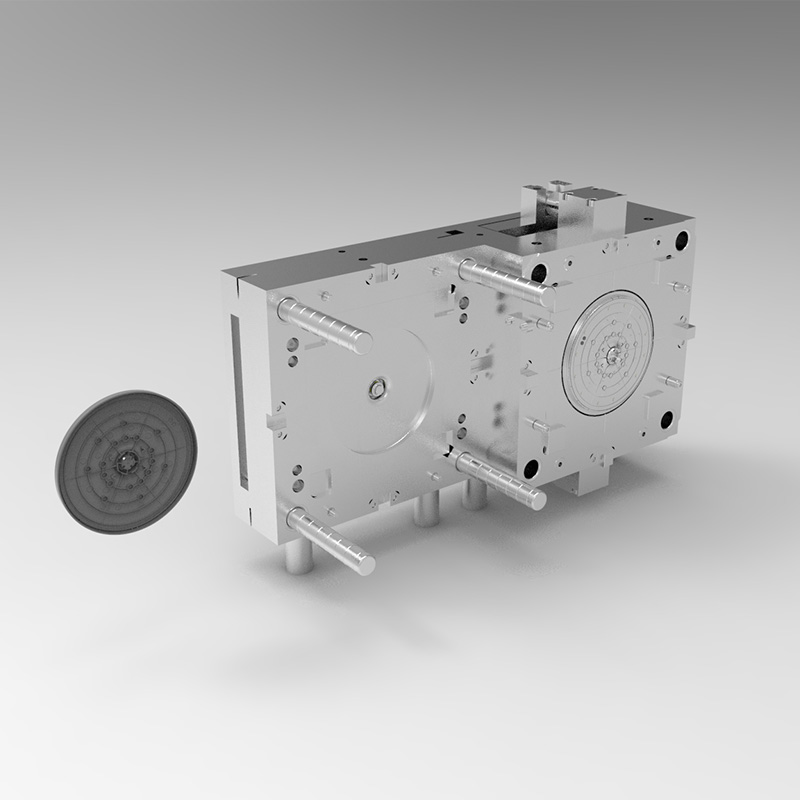

A customized plastic injection mold for a top shower or hand shower would be designed specifically to meet the requirements and specifications of the desired product. The mold would be created using high-quality materials and precision engineering techniques to ensure accuracy and durability.

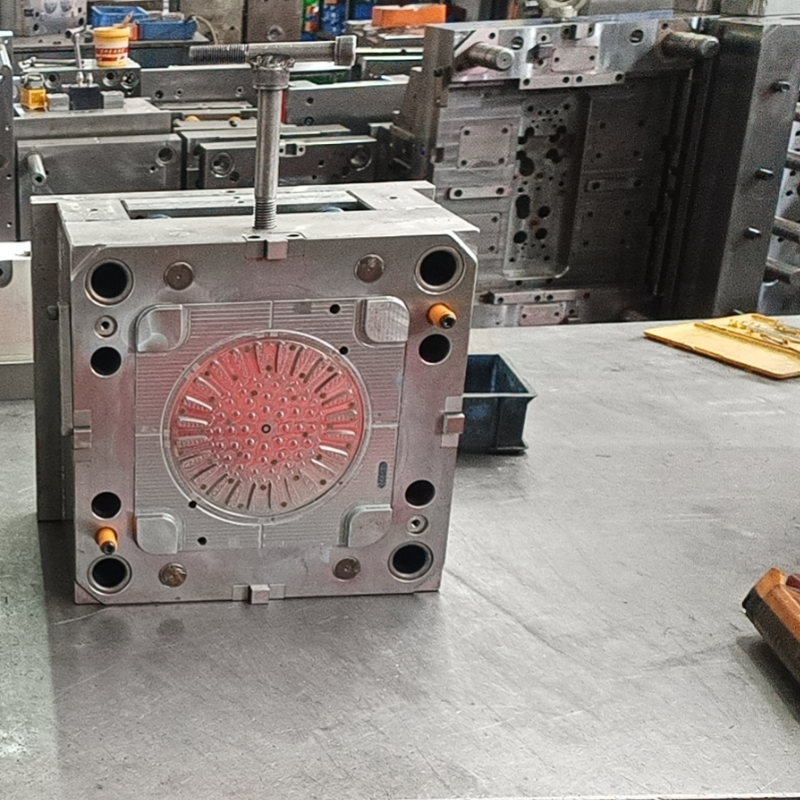

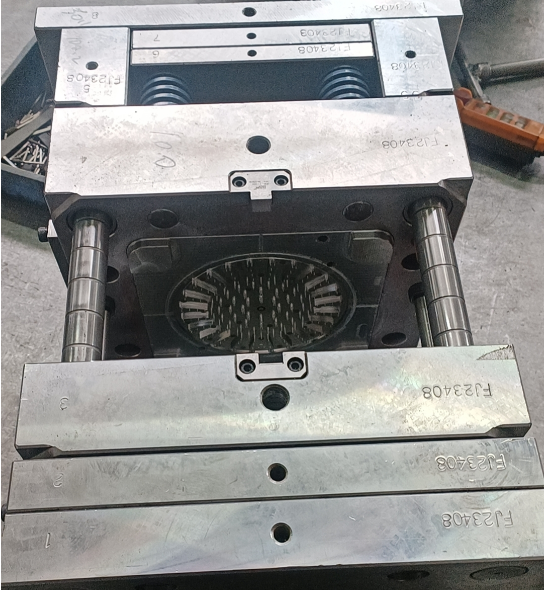

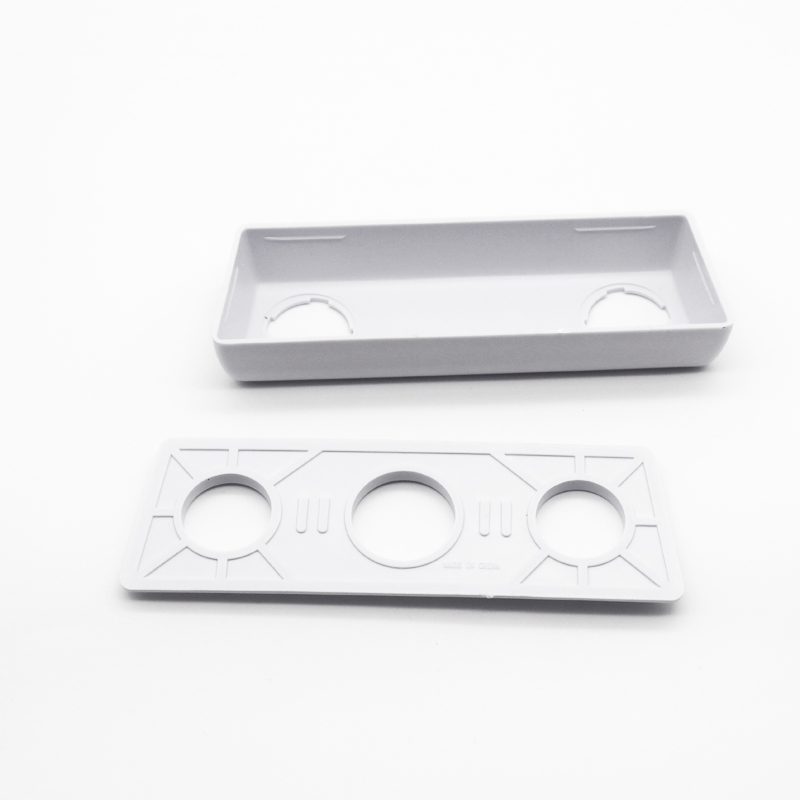

The mold would be designed to produce the desired shape and dimensions of the top shower or hand shower, including any unique features or details. This could include the shape of the showerhead, the size and placement of the nozzles, and any additional functions or attachments.

The mold would also incorporate any necessary inserts or cores to create the desired internal features or structures of the shower, such as water channels or pressure regulators. These inserts would be carefully designed and positioned within the mold to ensure proper functionality and ease of assembly.

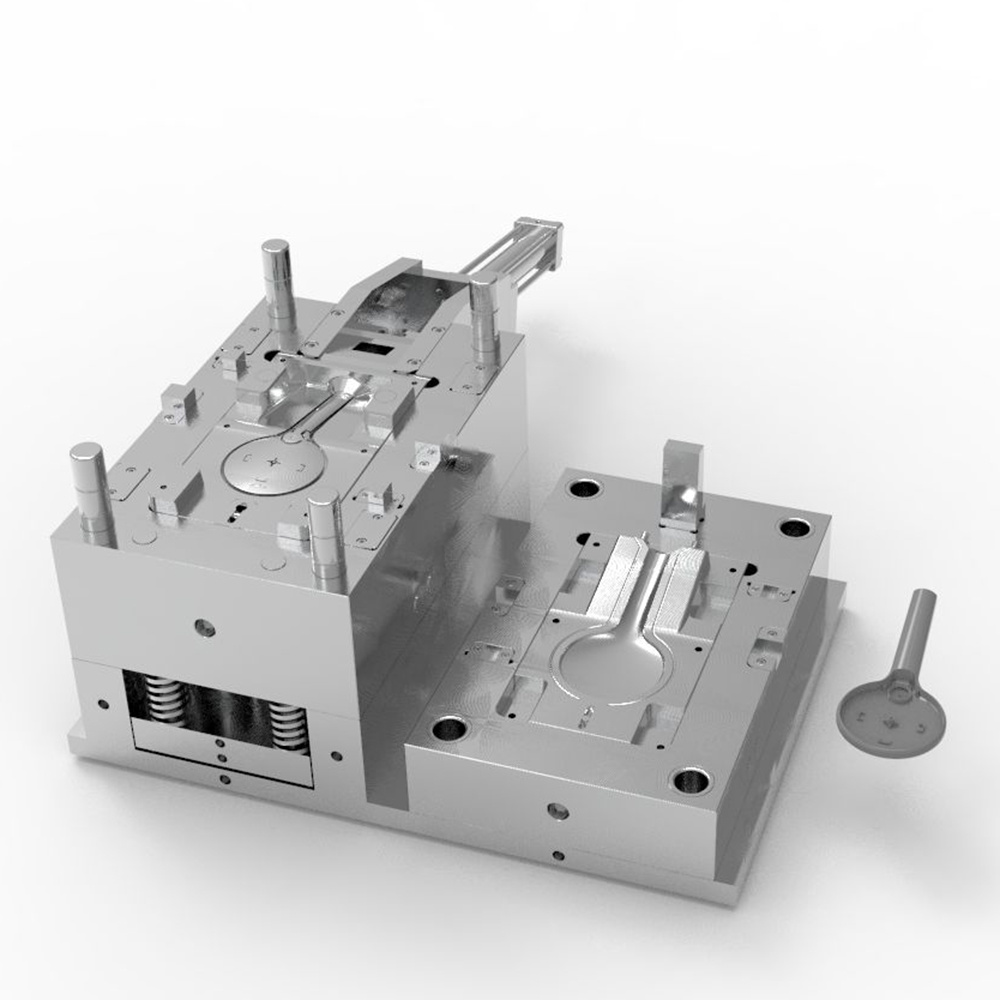

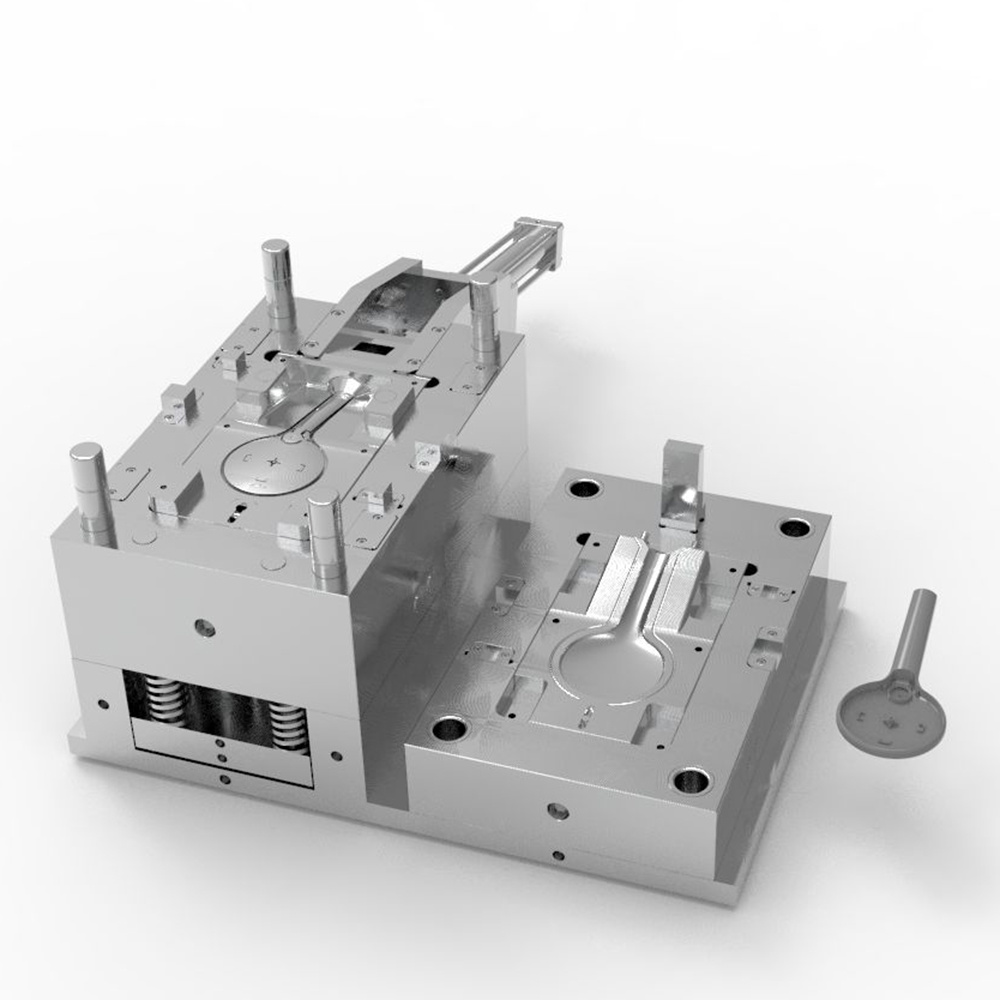

In addition to the shape and internal features, the mold would also include any necessary ejector pins or slides to facilitate the removal of the finished product from the mold. These mechanisms would be designed to minimize any potential damage to the part during the ejection process.

Plastic mold design refers to the process of creating a mold that is used to shape plastic materials into a desired form. It involves designing the mold structure, creating cavity and core components, and considering factors such as material flow, cooling, and ejection.

Here are some key steps in plastic mold design:

1. Product Design: Understand the requirements and specifications of the plastic part that needs to be molded. Consider factors such as dimensions, shape, and functionality.

2. Mold Structure Design: Determine the type of mold required, such as a two-plate mold, three-plate mold, or hot runner mold. Design the mold structure including the parting line, gating system, and ejection system.

3. Cavity and Core Design: Create the cavity and core components of the mold. Consider factors such as draft angles, surface finish, and tolerances to ensure proper plastic flow and easy ejection.

4. Runner and Gate Design: Design the runner system that delivers molten plastic from the injection molding machine to the mold cavity. Determine the gate location and size to control the flow of plastic into the mold.

5. Cooling System Design: Incorporate a cooling system into the mold to control the temperature and solidification of the plastic. Design cooling channels or inserts to ensure uniform cooling and minimize cycle time.

Product Specification:

| Customized Plastic Injection Mould For Top Shower /Hand Shower |

factory

| mould name

| mold cavity

| mold core

| mold base

| mold delivery time

| shot(times)

| circle time(second)

|

fengjin

| cold runner mold

| 1 | S136

| C50 | 50days

| 2000000

| 45

|

The largest injection machine we have

For mould customized,we can make in a wide range include sanitary,sports,household appliances,car parts and so on.Below are some parts we make for our customer

This is our injection area on third floor

Hand shower mould is one of our original product,we are super professional on this

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate