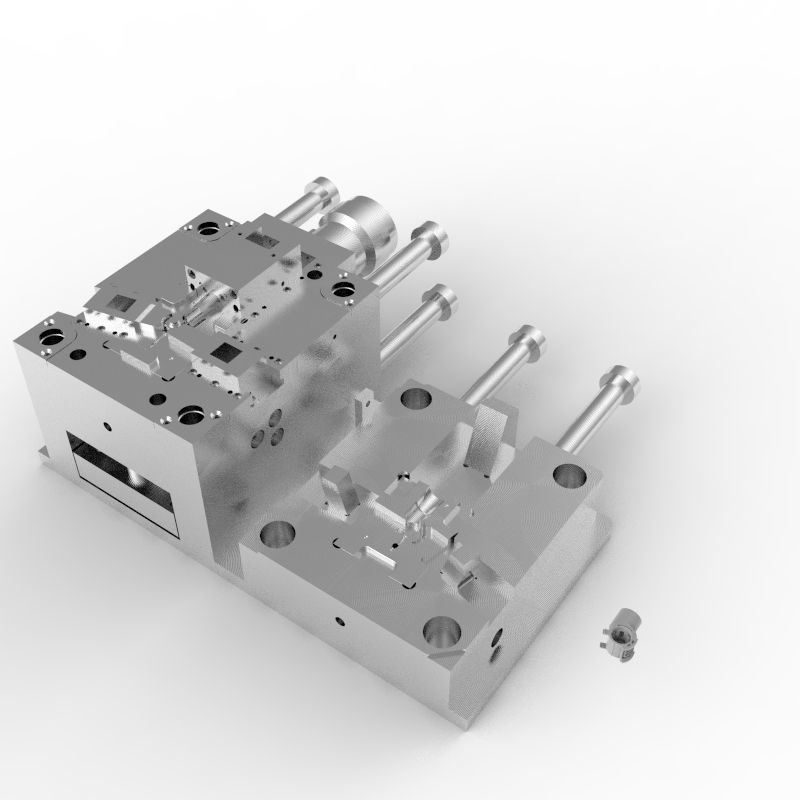

Plastic Mold Industy Make Family Mould For Bicycle Parts

The plastic mold industry has been a major contributor to the production of bicycle parts for many years. Plastic molds are used to create a wide variety of parts, including frames, forks, handlebars, brakes, and other components. The use of plastic molds has allowed manufacturers to create parts that are lightweight, durable, and cost-effective.

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:4

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

The production of bicycle parts using plastic molds is a complex process. First, the mold is created using a CAD program. This allows the mold maker to create a design that is precise and accurate. The mold is then heated and cooled in order to harden the plastic. After the plastic is hardened, it is then cut and shaped into the desired shape.Once the mold is cut and shaped, it is then ready to be used in the production of bicycle parts. The plastic is then heated again and injected into the mold. This process is known as injection molding. The injection molding process is used to create a variety of parts, such as pedals, handlebars, brakes, and other components.

Product Specification:

|

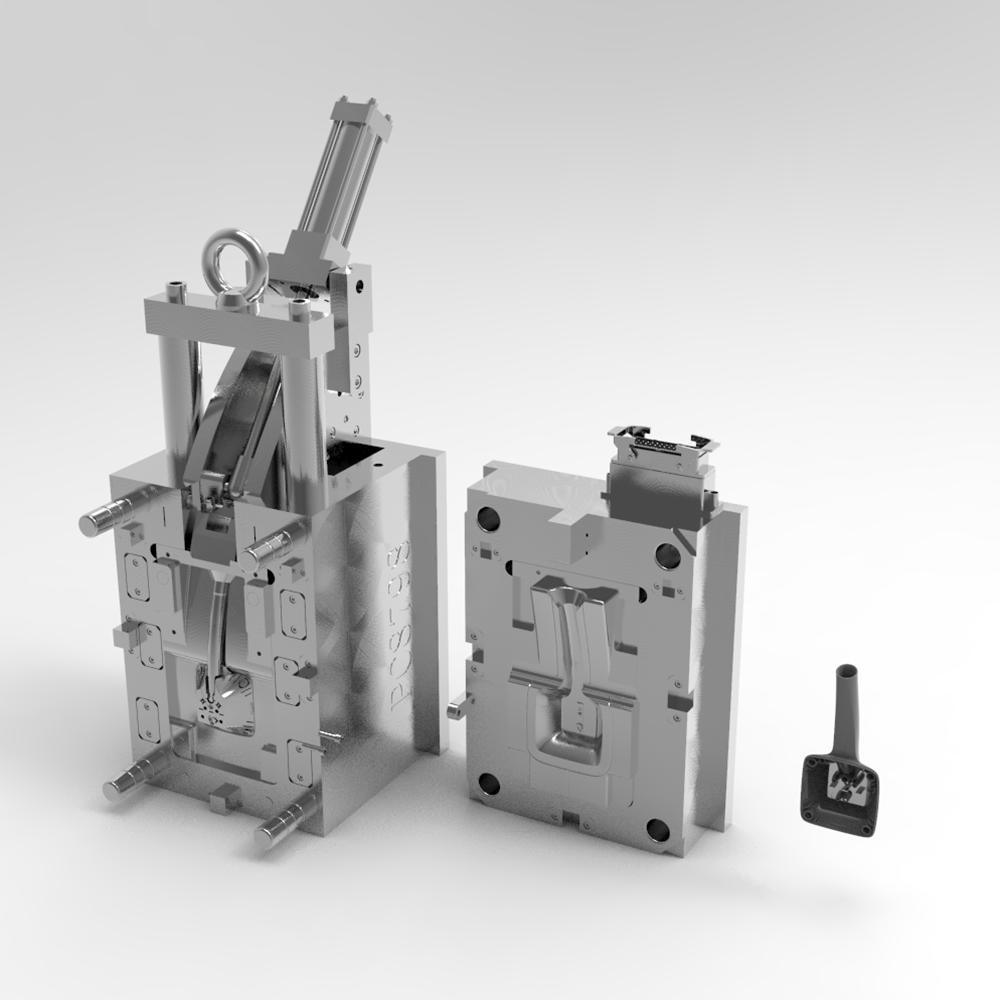

Plastic Injection Mould Manufacturing For Hand Shower |

|||||||

|

factory |

mould name |

mold cavity |

mold core |

mold base |

mold delivery time |

shot(times) |

circle time(second) |

|

fengjin |

hand shower mold |

2 |

S136 |

45# |

40days |

300000 |

95 |

The injection molding process is also used to create family molds. Family molds are used to create multiple parts from a single mold. This means that the same mold can be used to create multiple parts, saving time and money for the manufacturer. Family molds are also used to create parts with intricate details, such as intricate designs or logos.The plastic mold industry has been a major contributor to the production of bicycle parts for many years. The use of plastic molds has allowed manufacturers to create parts that are lightweight, durable, and cost-effective. Family molds are an important part of the plastic mold industry and are used to create multiple parts from a single mold. The injection molding process is used to create a variety of parts, such as pedals, handlebars, brakes, and other components. The use of family molds and injection molding has allowed manufacturers to create parts with intricate designs and logos

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Plastic Injection Mould Manufacturing For Hand Shower

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order