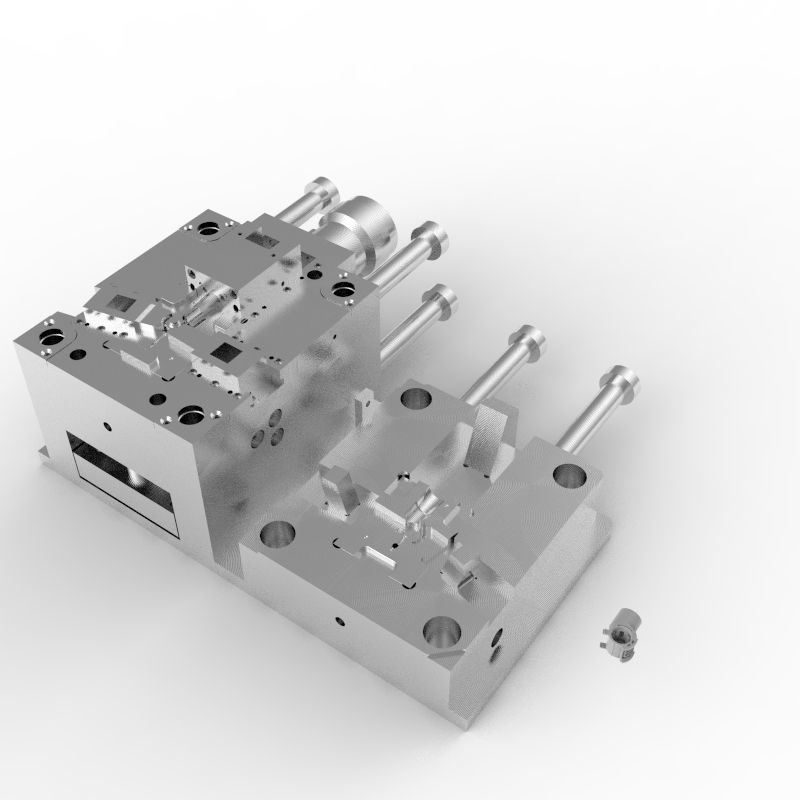

Plastic Injection Molding For Car Parts

Manufacturing Technique:injection plastic

Mould Core:S136

Mould Base :45# steel

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

Plastic injection molding for car parts begins by creating a mold, which is usually made from metal. The mold is then heated and plastic pellets are melted and injected into the mold. The molten plastic is then cooled and the part is removed. The cooling process can take anywhere from a few seconds to several minutes, depending on the complexity of the part.Once the part is removed from the mold, it is typically trimmed, sanded, and polished to the desired finish. This step is important to ensure that the part is free of defects and has a smooth surface. The part is then inspected to ensure that it meets the manufacturer's specifications.The next step in the process is to assemble the part. This may involve attaching other components, such as screws and bolts, or adding additional features to the part, such as paint or chrome plating. Once the part is fully assembled, it is ready for installation.All are mould and production are finish in this three floor building.

Product Specification:

|

Plastic Injection Molding For Car Parts |

|||||||

|

factory |

mould name |

mold cavity |

mold core |

mold base |

mold delivery time |

shot(times) |

circle time(second) |

|

fengjin |

auto parts mould |

2 |

S136 |

45# |

40days |

300000 |

95 |

Plastic injection molding is a popular choice for car makers due to its cost-effectiveness, speed, and accuracy. It is also a relatively simple process, making it easy to learn and use. The process is also very versatile, allowing for the creation of a wide variety of car parts

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order