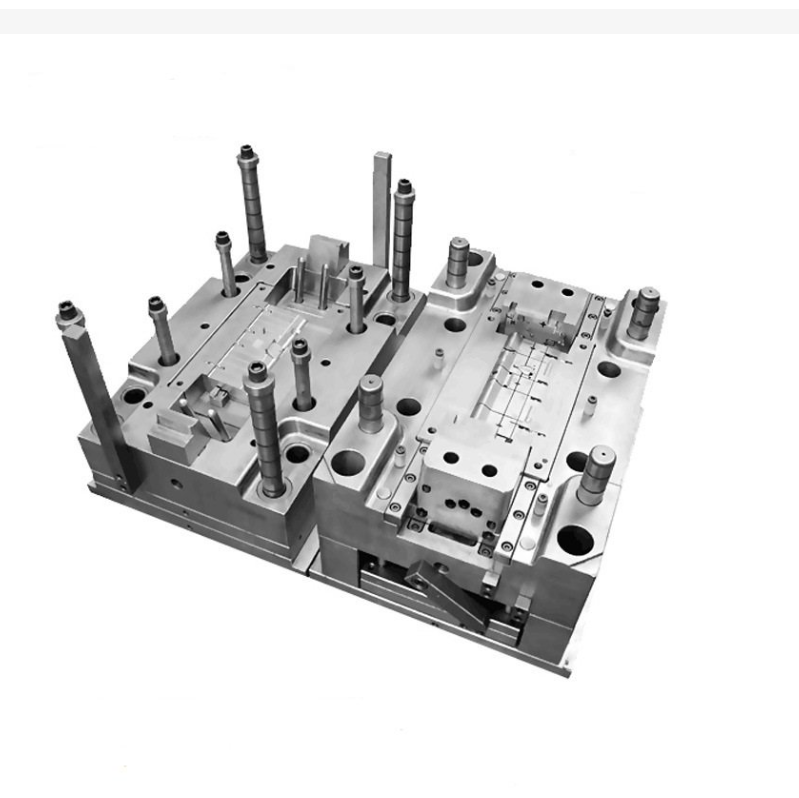

Injection Moulding Car Parts Like Mobile Phone Holder Mould

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:2

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

Injection moulding is a process used to create car parts such as mobile phone holders. It involves heating a plastic material and forcing it into a mould cavity to form the desired part. The process is often used by automotive manufacturers to create complex parts that require precise dimensions.

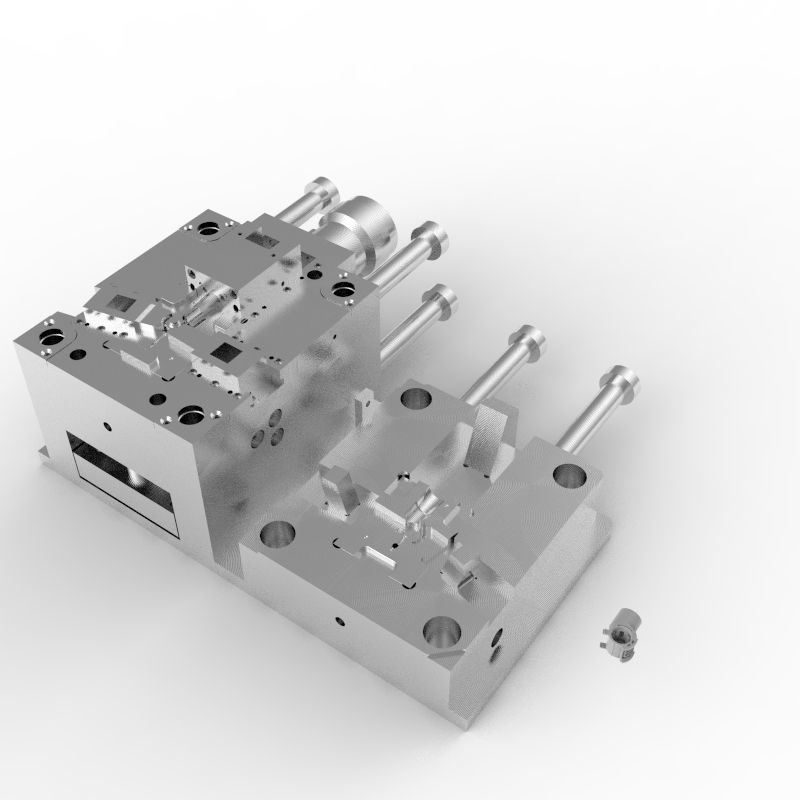

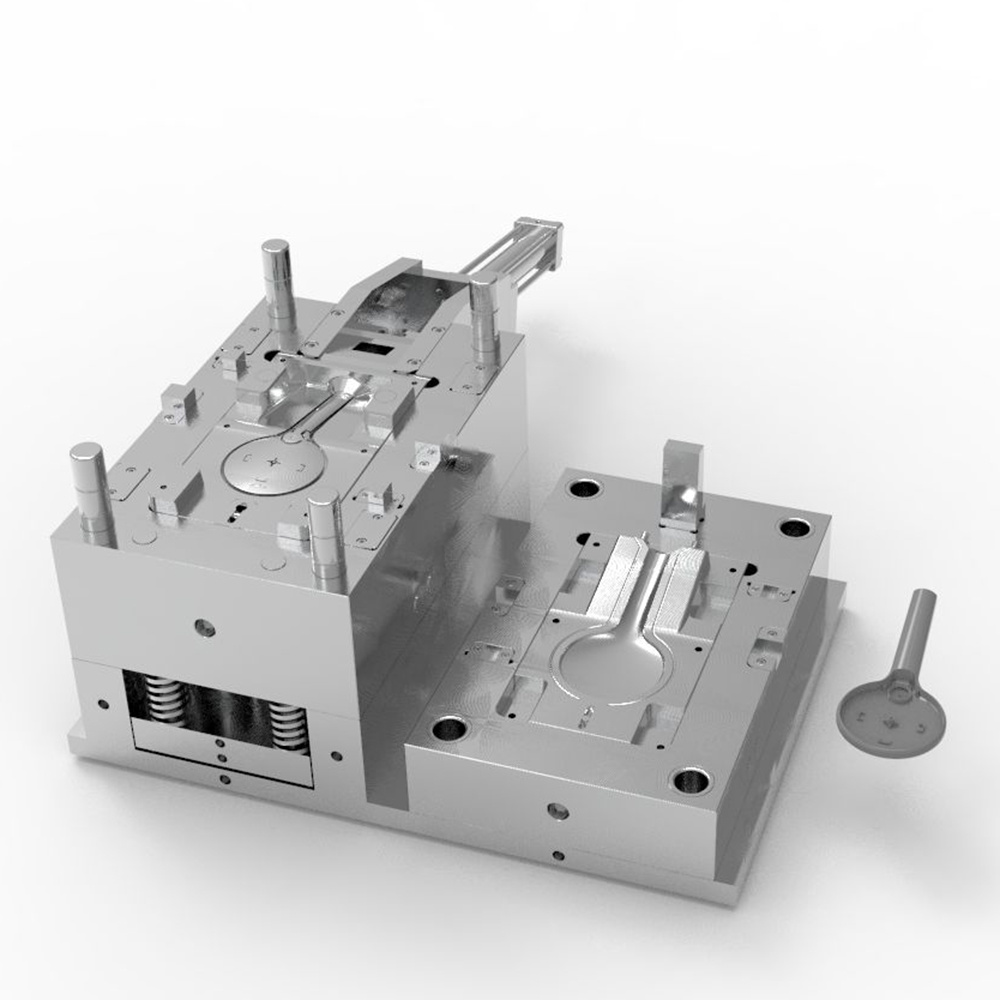

The process of injection moulding starts with the selection of the raw material, which is typically a thermoplastic or thermoset material. The material is then melted in an injection moulding machine and injected into the mould cavity. The mould cavity is typically made from metal and is designed to match the shape and size of the part being produced. The molten material is then cooled and hardened in the mould cavity.

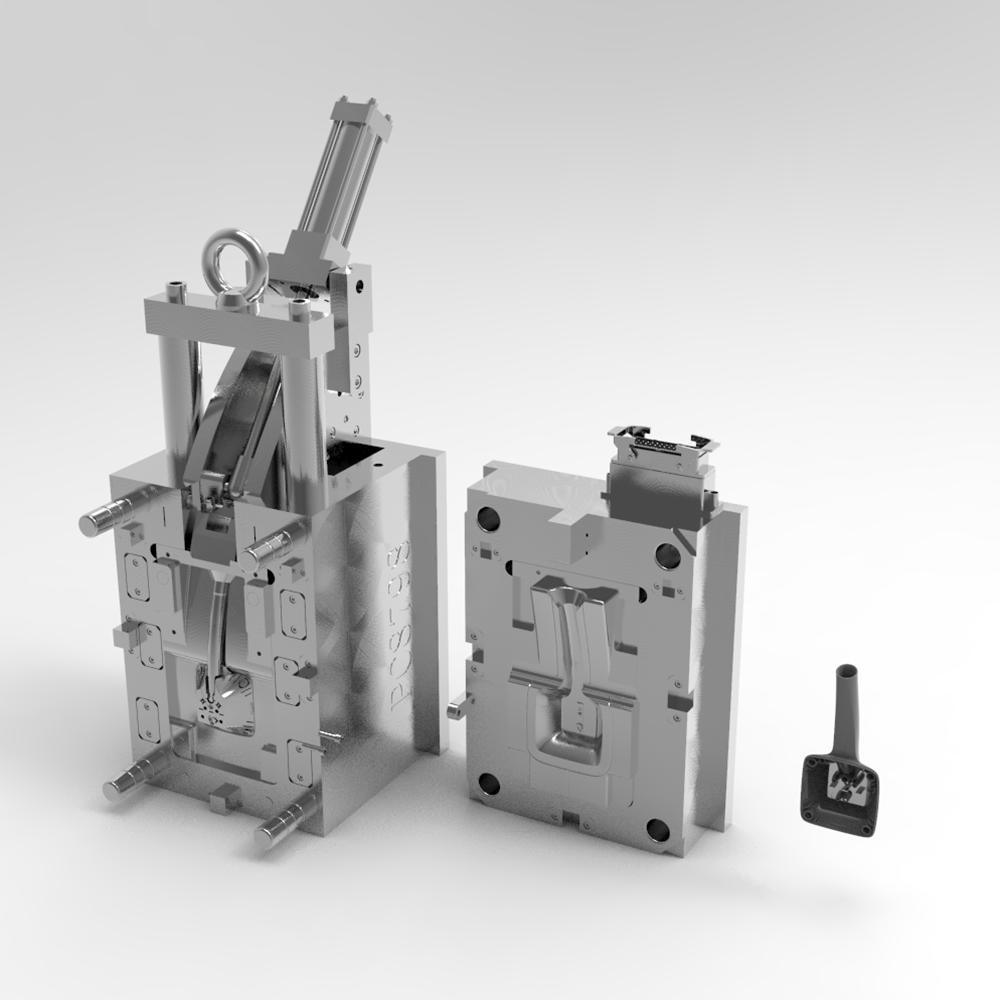

Phone holder mould is well design by mould factory with different shape to fit different brand and size phone,it make driver converient to use or navigate while driving,when mould is done,the injection machine will start to make samples to test the quality,if samples is good will start mass production and QC will check one by one and then start packing.After that,the phone holder will went into the market and sell,the user will have it ,the cost is not expensive but can use many year if you want,only when you don't like it and want to change a new style and different one,the mould designer is always keep develop new one.

Product Specification:

| Injection Moulding Car Parts Like Mobile Phone Holder Mould | |||||||

|

factory |

mould name |

mold cavity |

mold core |

mold base |

mold delivery time |

shot(times) |

circle time(second) |

|

fengjin |

phone holder mould |

1 |

S136 |

45# |

40days |

300000 |

45 |

Injection moulding is a versatile process that can be used to produce a wide range of parts. It is ideal for producing complex parts with intricate details, as well as parts with large surface areas. The process is also suitable for producing parts with a variety of materials, including metal alloys, plastics, and composites.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Our other plastic injection mould products

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate