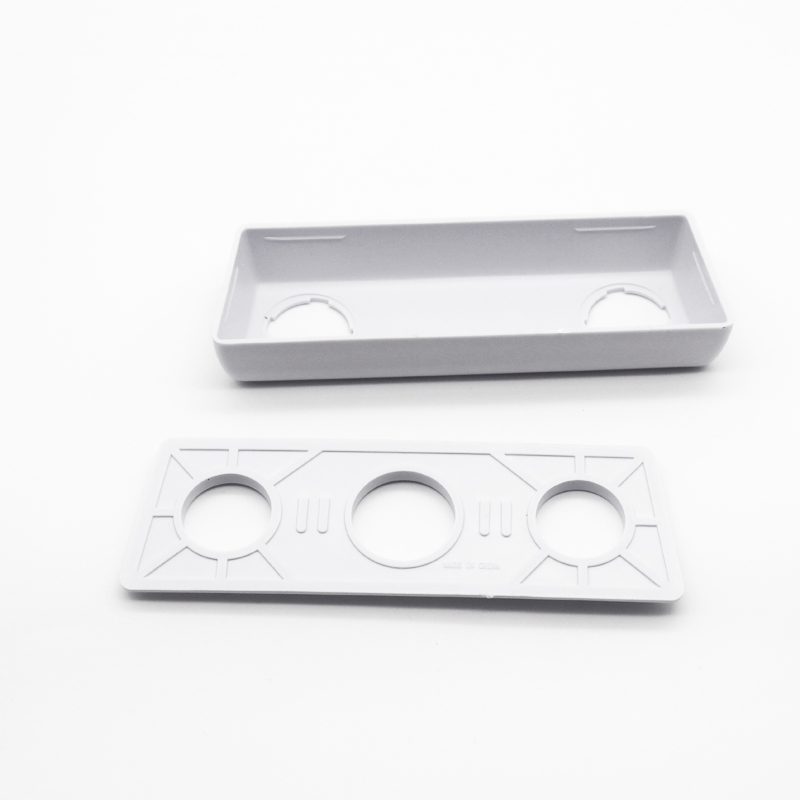

electroplating-plastic-faucet-bathroom-sink-faucets

Manufacturing Technique:plastic injection

Product Material:abs

usage :bathroom faucet

Factory Location:Xiamen,China

customized packing avaiable

Kep Words:bathtub faucet

We have 8 items plastic faucet with electroplating ready to delivery,and we can offer customized service for new deisgn from mould to production for customer.

Product Specification:

| Electroplating Plastic Faucet bathroom sink faucets | |||||||

factory | name | matierial | process | delivery time | packing | ||

fengjin | faucets | abs | lectroplating | 0 | 15days | brown box | |

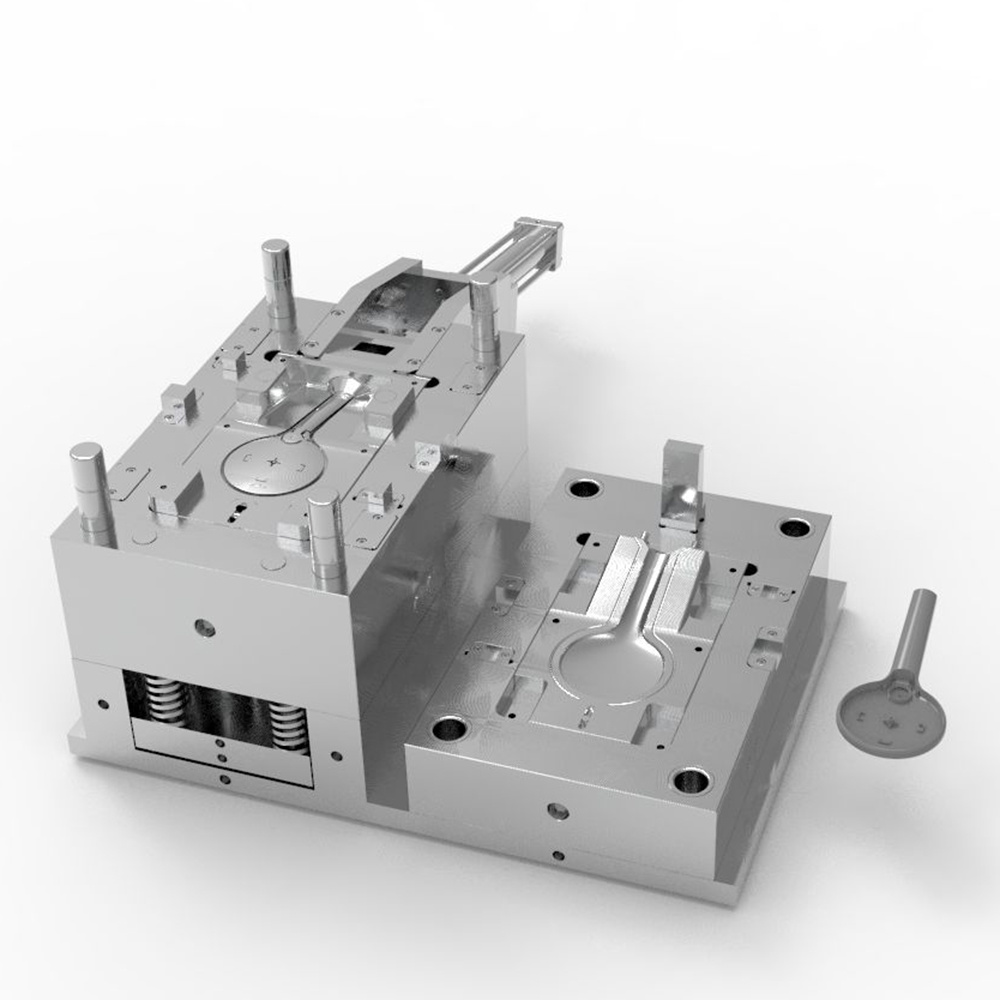

The largest injection machine we have

For mould customized,we can make in a wide range include sanitary,sports,household appliances,car parts and so on.Below are some parts we make for our customer

This is our injection area on third floor

Hand shower mould is one of our original product,we are super professional on this

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate