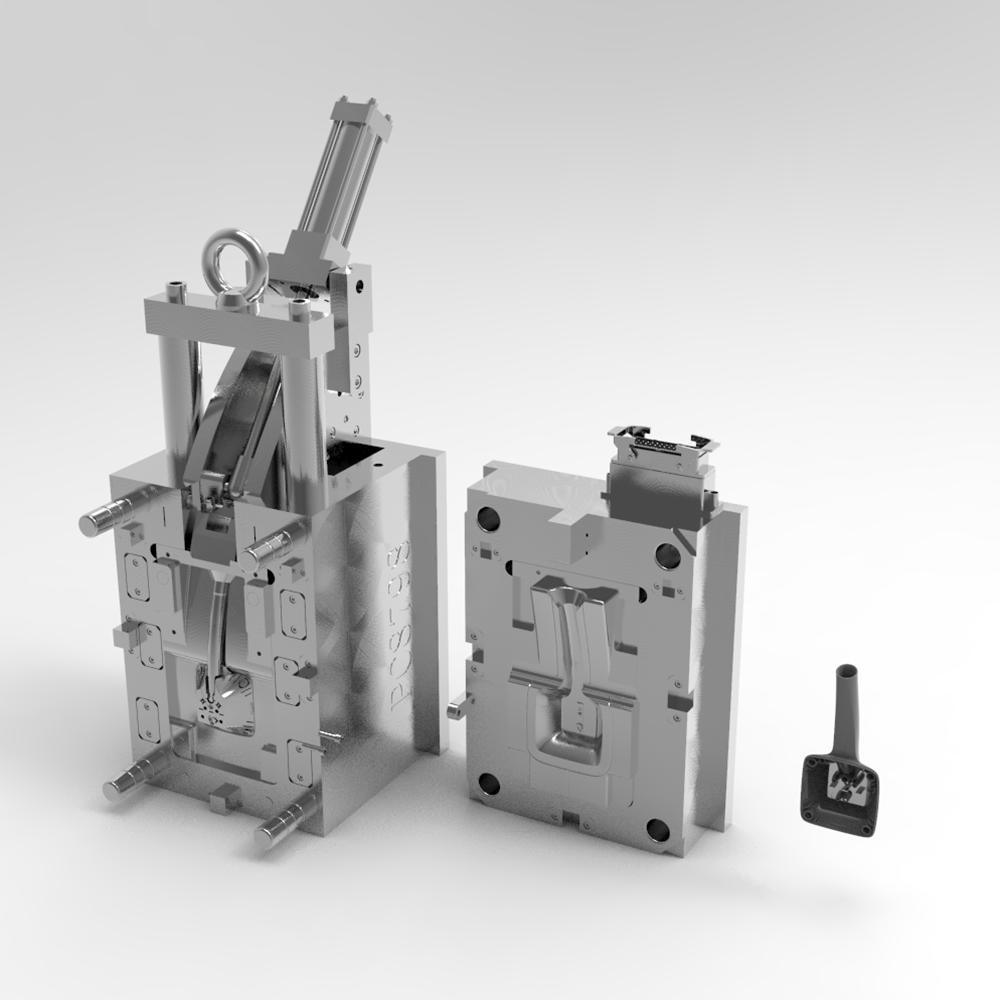

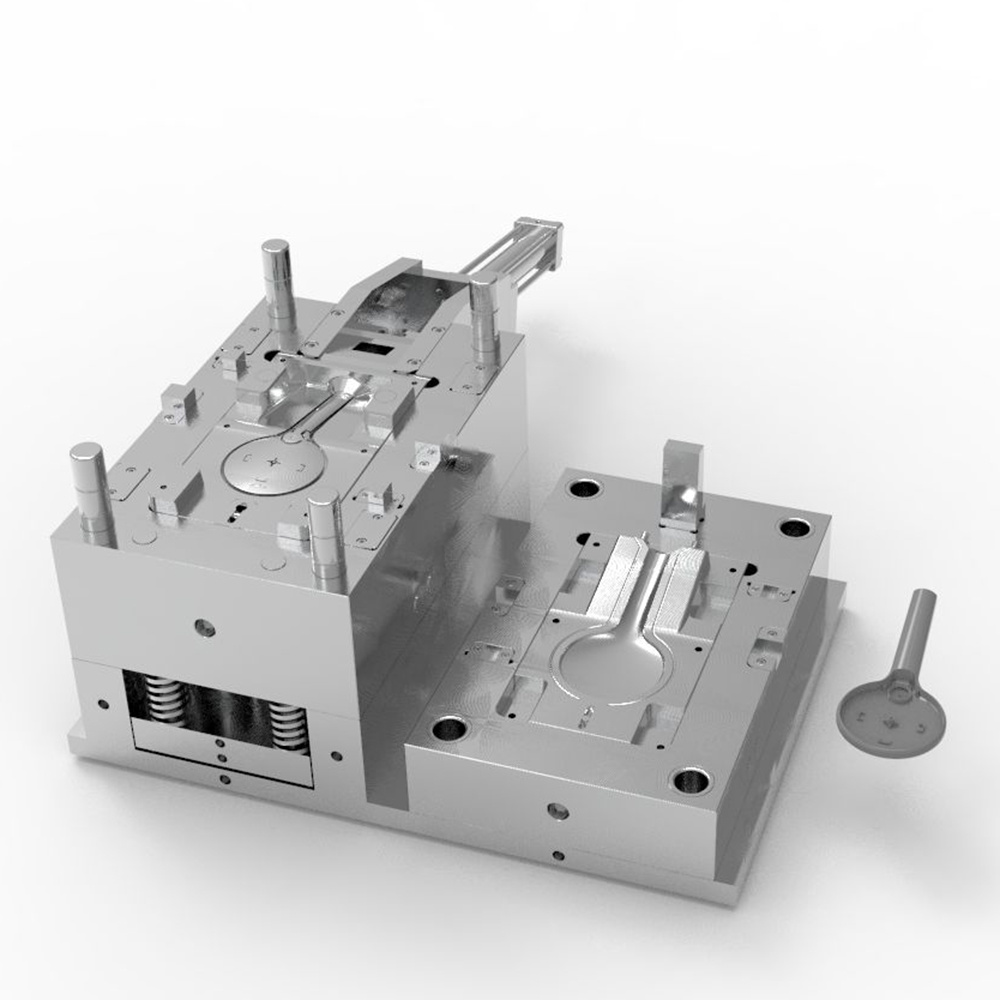

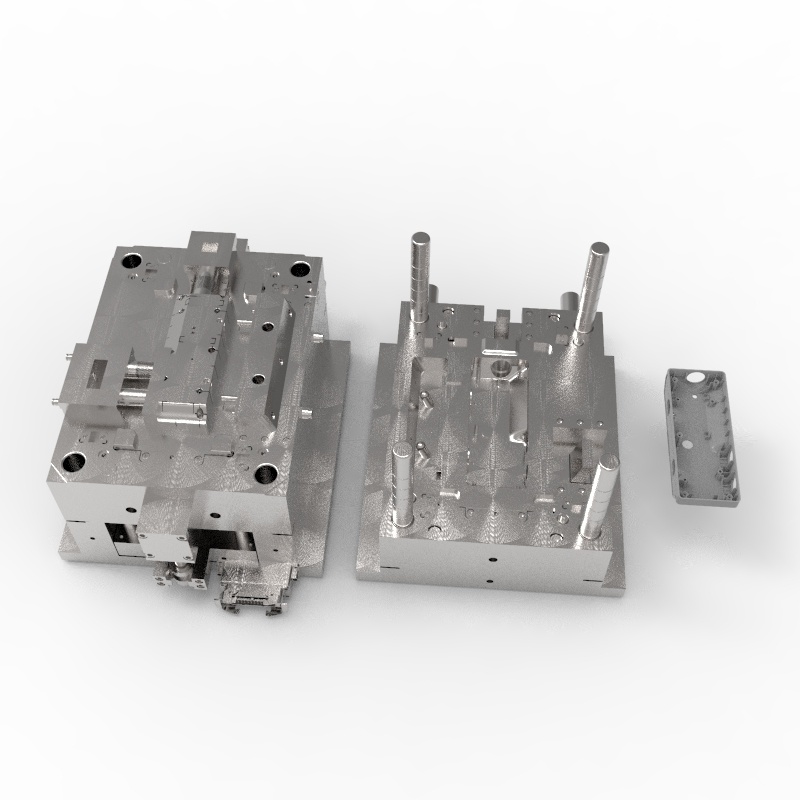

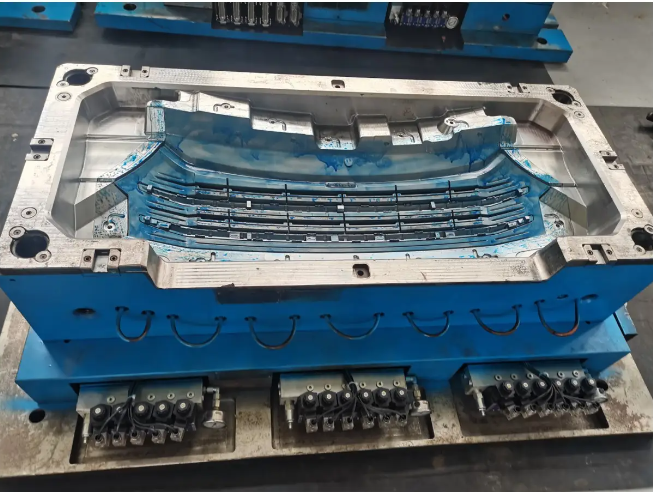

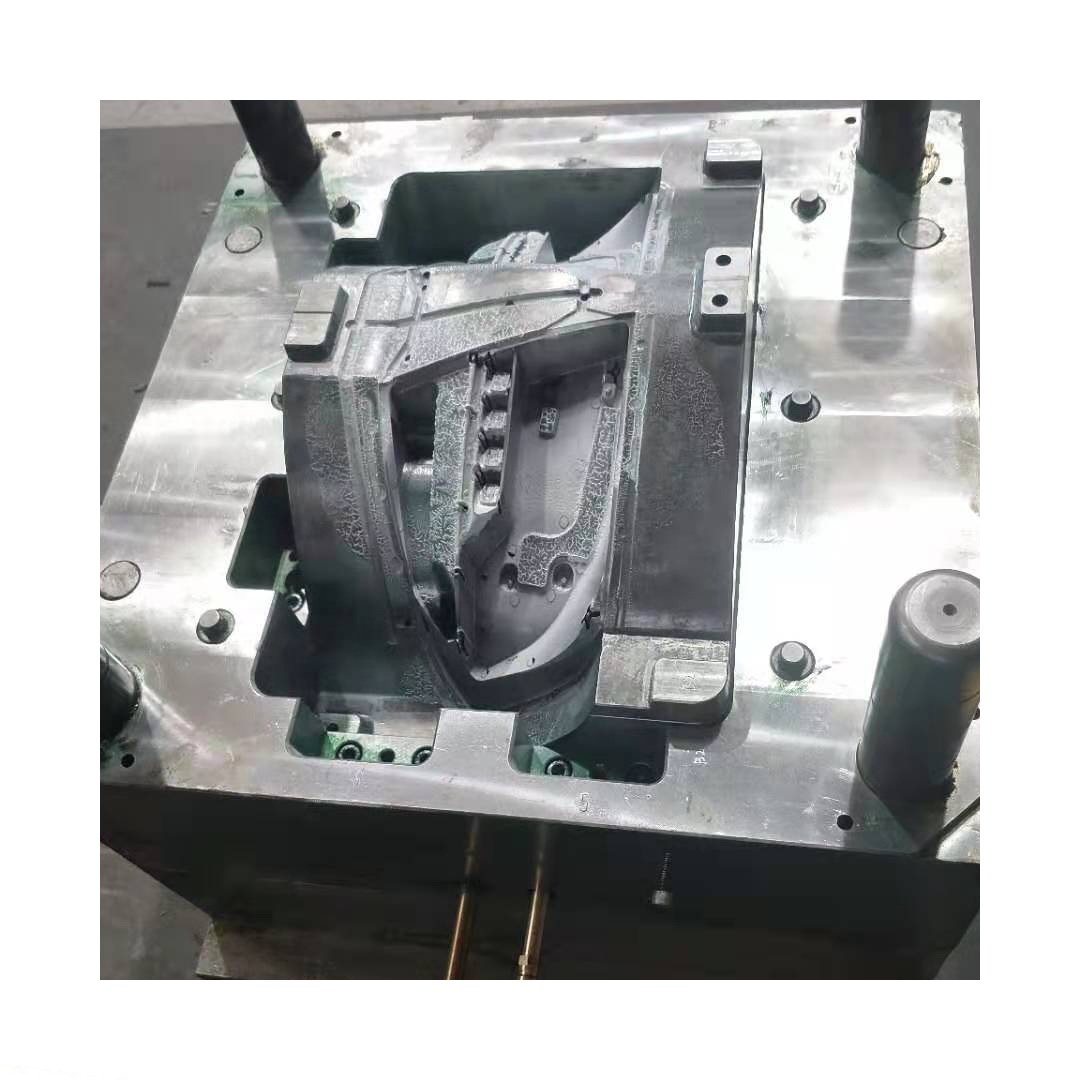

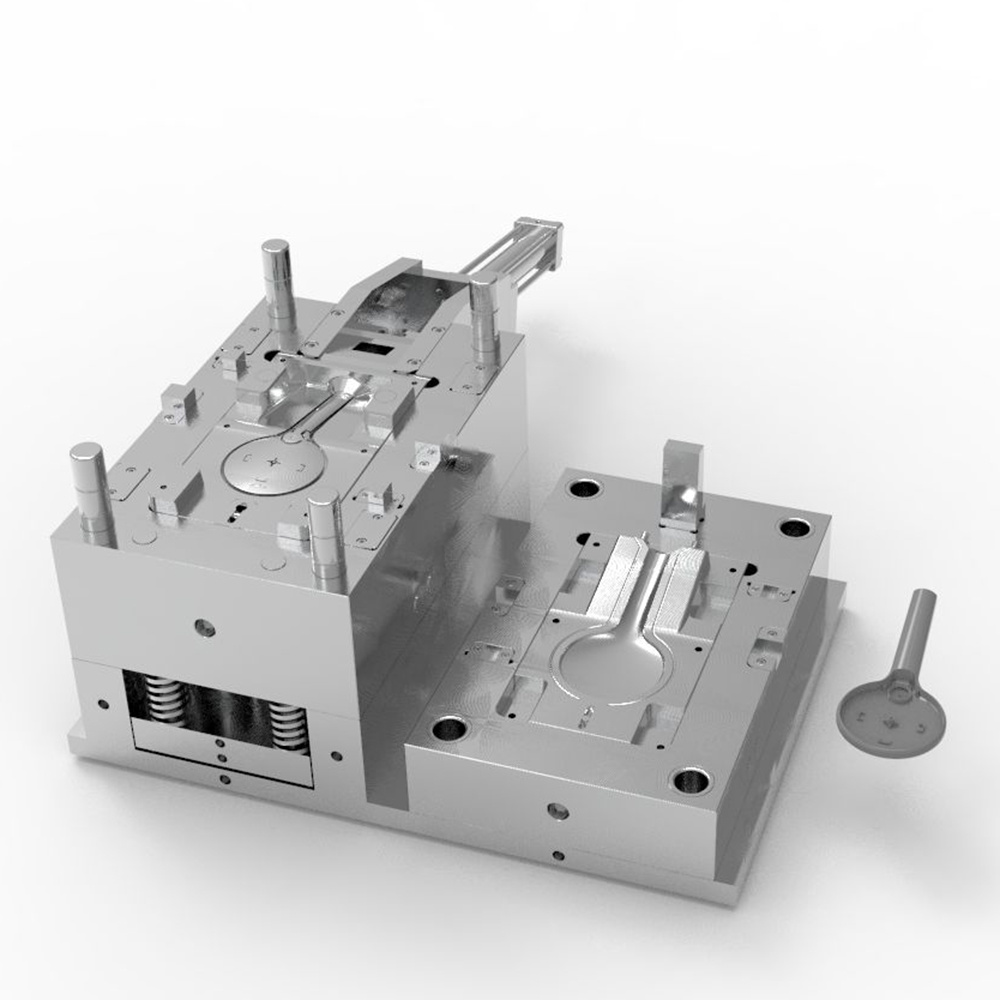

Injection Molded For Car Plastic Components

Manufacturing Technique:injection

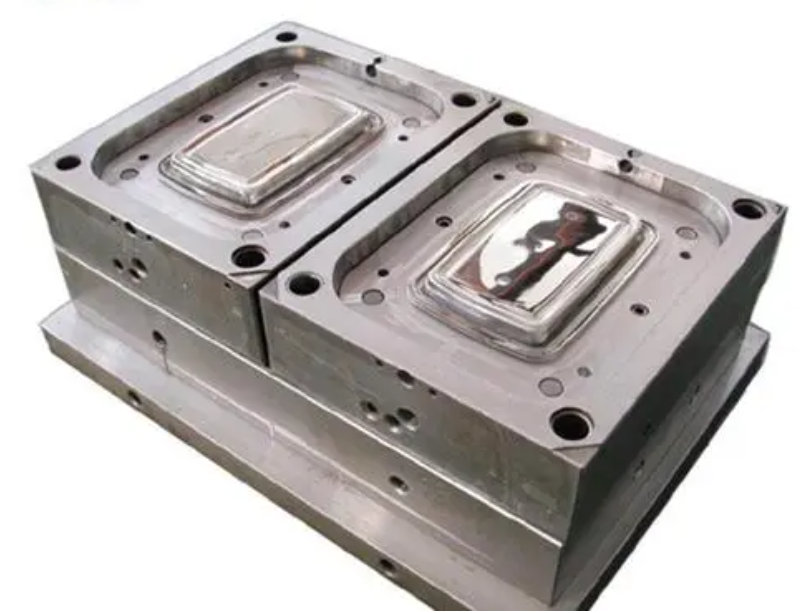

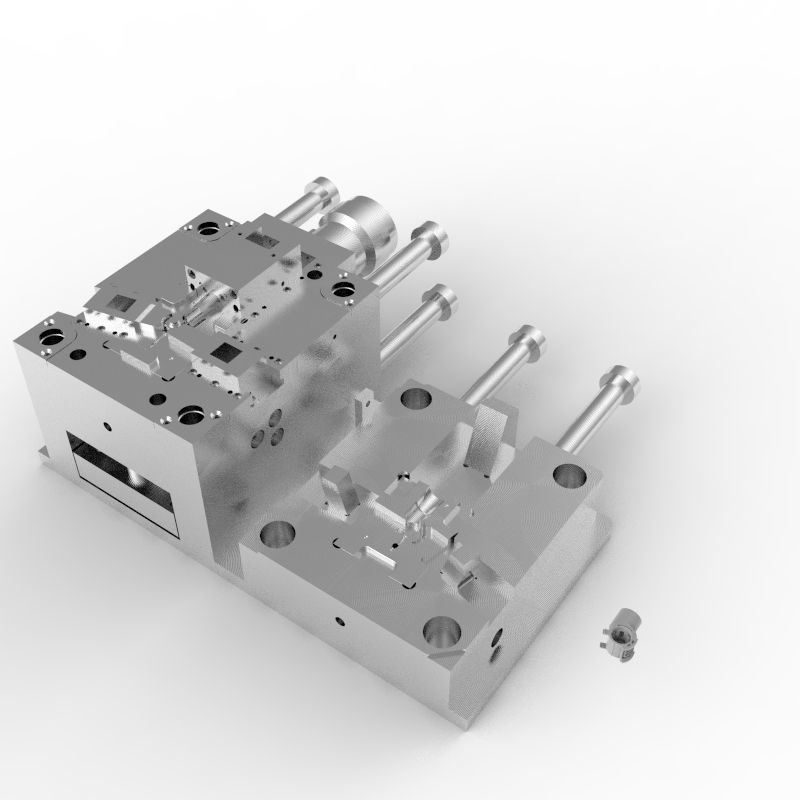

Mould Core:S136

Mould Base :45# steel

Cavity:1

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

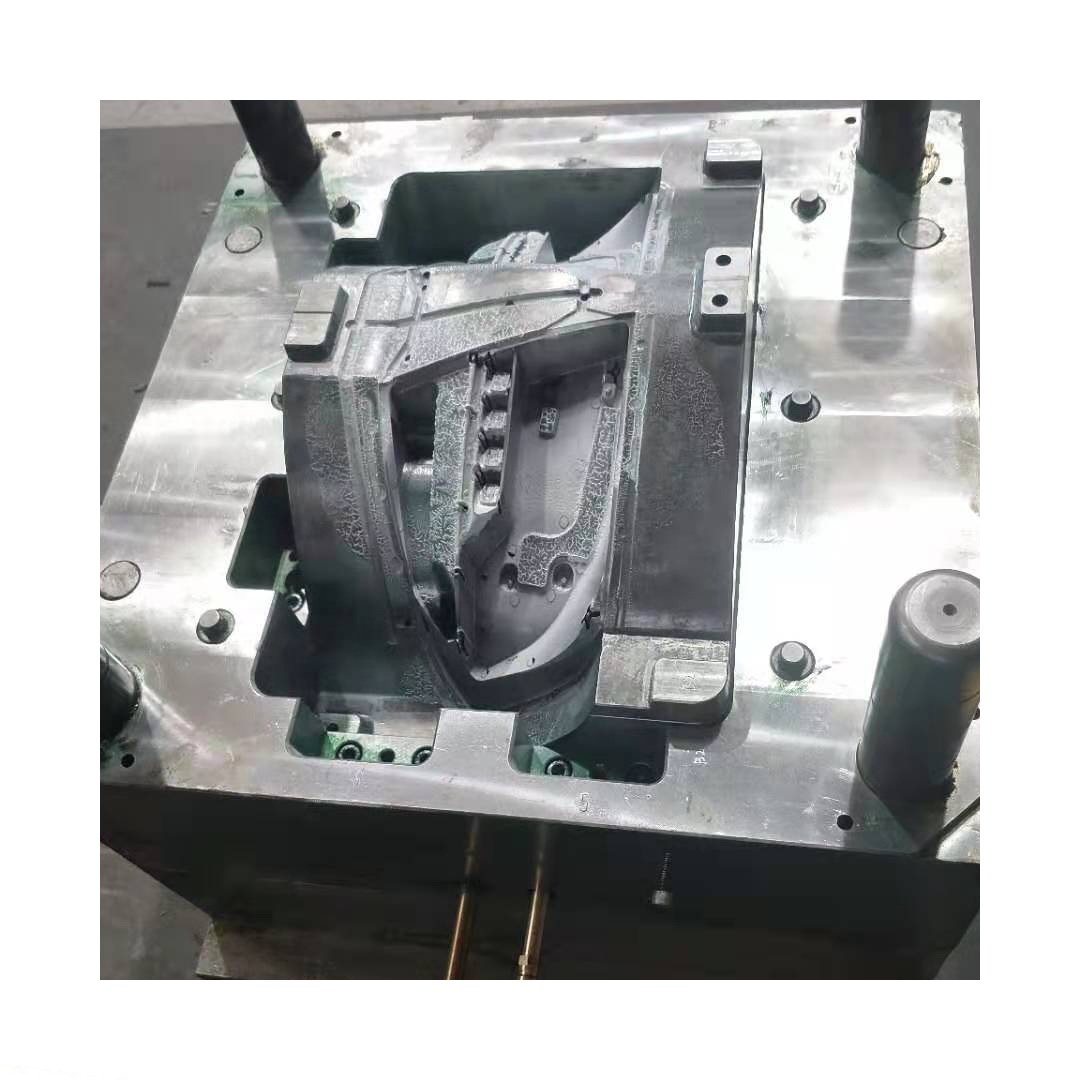

Injection molding can be used to create a wide range of car plastic components, including body panels, interior trim pieces, bumpers, and under-hood components. The process is also well-suited for producing small parts, such as clips and fasteners, which can often be difficult to produce using other methods.

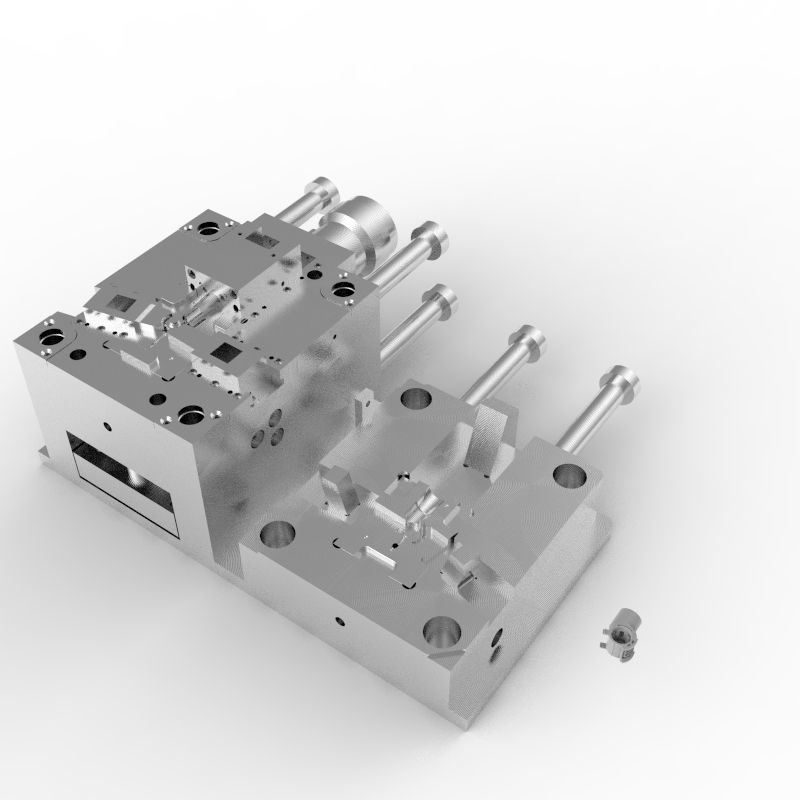

The injection molding process is highly automated, allowing for high volumes of components to be produced quickly and with a high degree of accuracy. The process is also highly repeatable, meaning that the same part can be produced multiple times with the same results each time. This helps to ensure that the part or component meets its specifications and that it is of the highest quality.

Product Specification:

| Injection Molded For Car Plastic Components |

factory

| mould name

| mold cavity

| mold core

| mold base

| mold delivery time

| shot(times)

| circle time(second)

|

fengjin

| car plastic components | 1

| S136

| 45#

| 40days

| 300000

| 95

|

Injection molding is a cost-effective way to produce plastic components for cars. The process is fast and accurate, resulting in strong and durable parts. The process is also well-suited for producing small parts, such as clips and fasteners, making it a popular choice for car manufacturers. With its high degree of automation and repeatability, injection molding is an ideal choice for creating car plastic components.

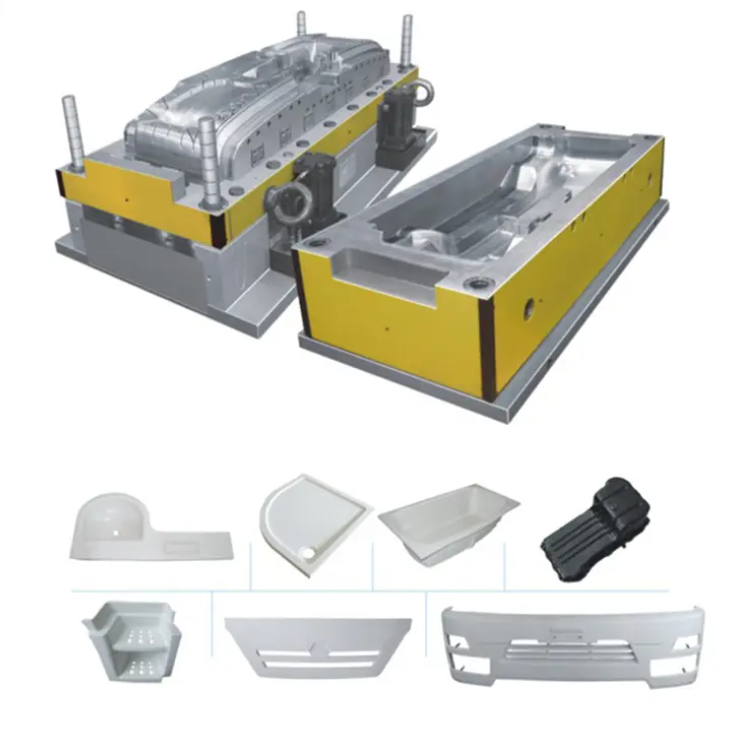

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

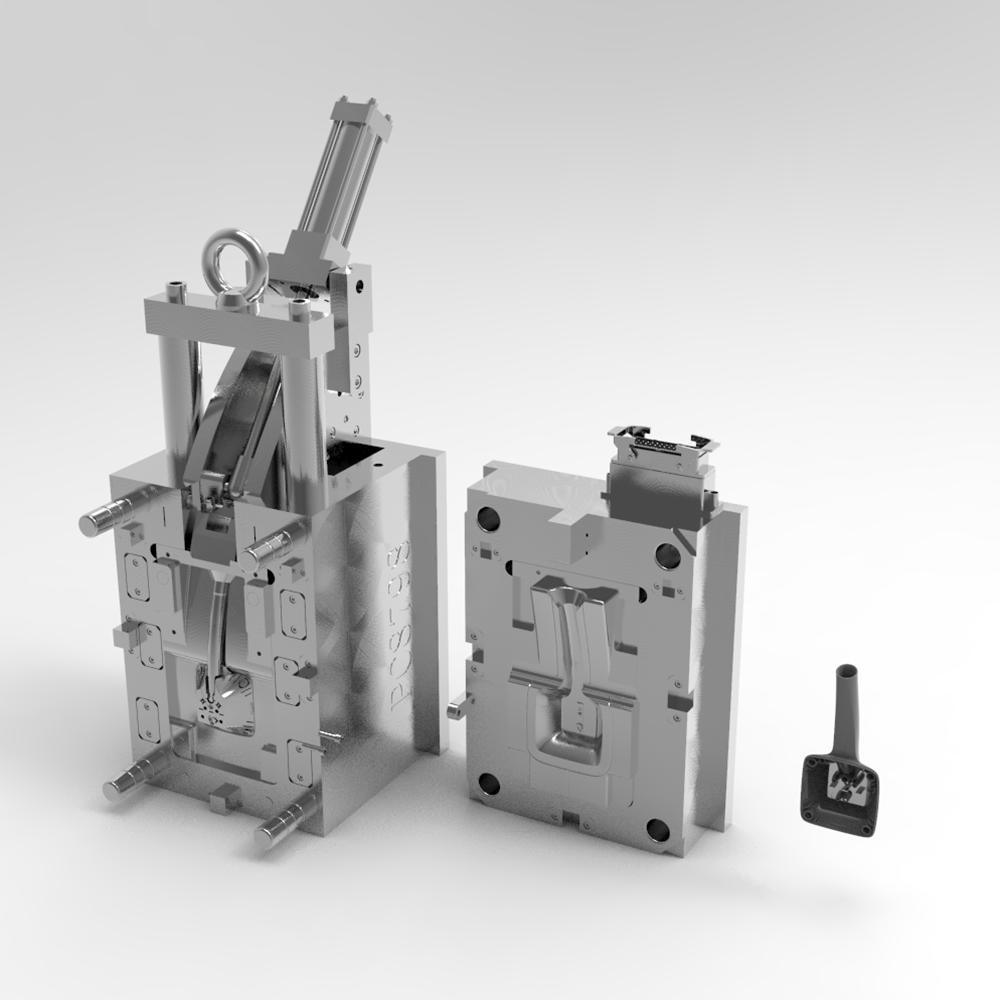

Plastic Injection Mould Manufacturing For Hand Shower

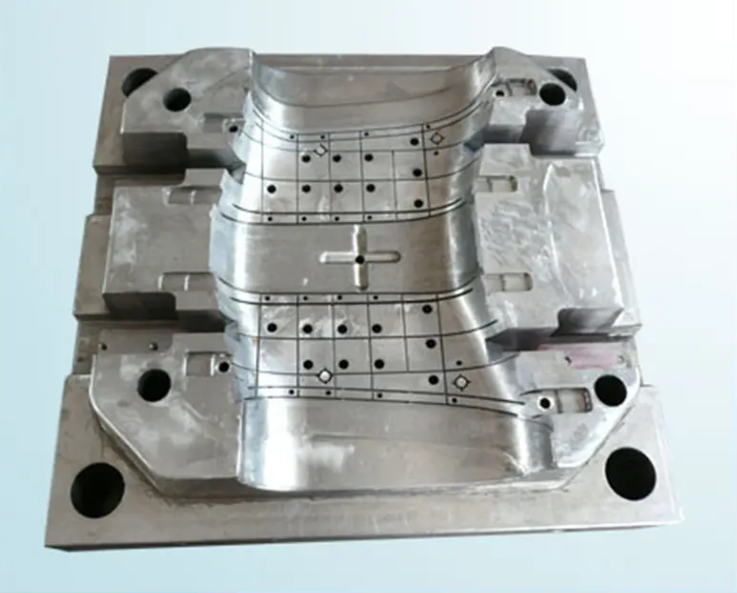

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate