Hot Runner Plastic Injection Molding For Sports Equipment

Manufacturing Technique:injection

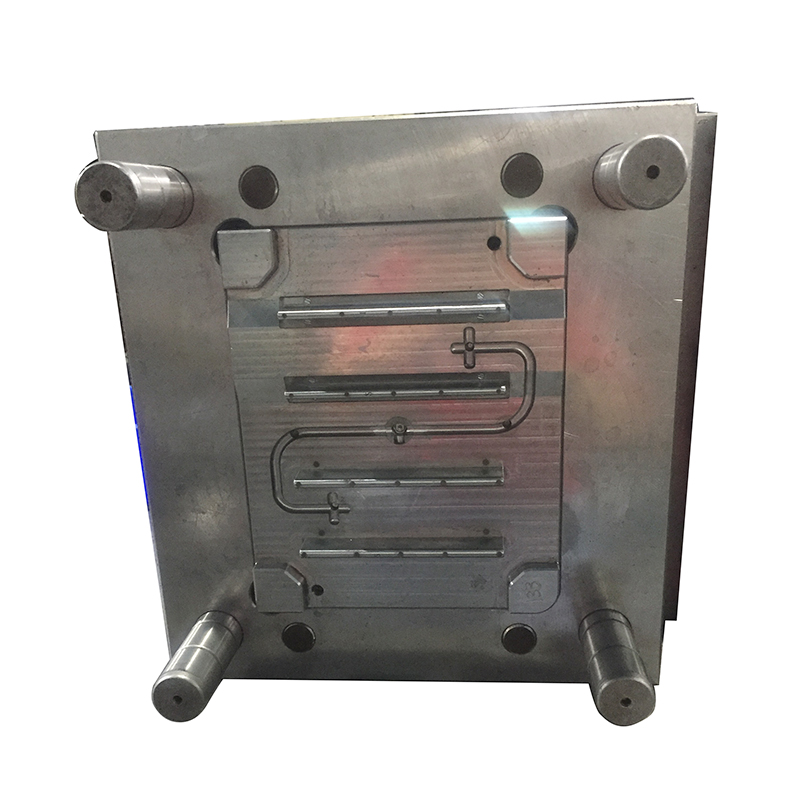

Mould Core:S136

Mould Base :45# steel

Cavity:1

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

Hot runner moulds are an advanced type of injection moulding technology used to create high-quality plastic parts with greater efficiency and accuracy. The process involves the use of a heated manifold to inject molten plastic directly into the mould cavity, eliminating the need for a runner system and reducing the amount of plastic waste generated. Hot runner moulds are typically used for parts with complex shapes and intricate details, as well as parts with tight tolerances and high-precision requirements. The process is also ideal for producing parts with a variety of colors and textures.

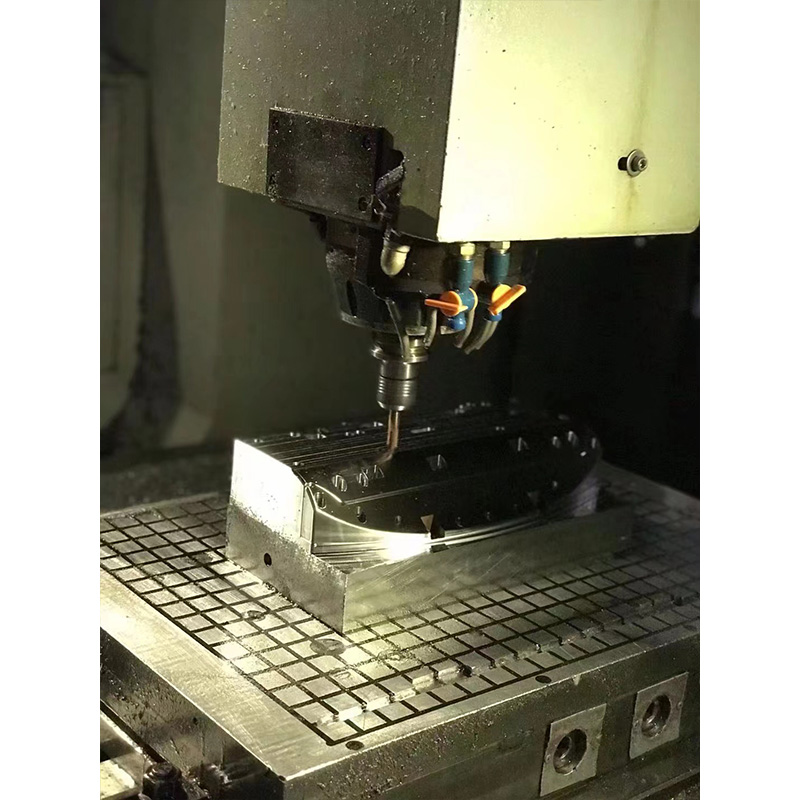

The hot runner moulding process begins with the injection of molten plastic into the heated manifold. The heated plastic is then injected into the mould cavity through a series of nozzles, which are connected to the manifold. The nozzles are designed to provide the right amount of pressure and flow rate to ensure that the plastic is evenly distributed throughout the mould cavity. Once the plastic has been injected, the mould is then cooled to solidify the part.

Product Specification:

| Hot Runner Plastic Injection Molding For Sports Equipment |

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | hot runner plastic injection mould | 1 | S136 | 45# | 40days | 300000 | 95 |

The advantages of using hot runner moulds include increased efficiency, reduced waste, and improved part quality. The process is more efficient because it eliminates the need for a runner system, which can add time and cost to the injection moulding process. Hot runner moulds also produce less waste, as the plastic is injected directly into the mould cavity, eliminating the need for a runner system. Finally, the improved part quality is due to the even distribution of plastic throughout the mould cavity, which results in parts with greater accuracy and consistency.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Hot Runner Plastic Injection Molding For Sports Equipment

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate