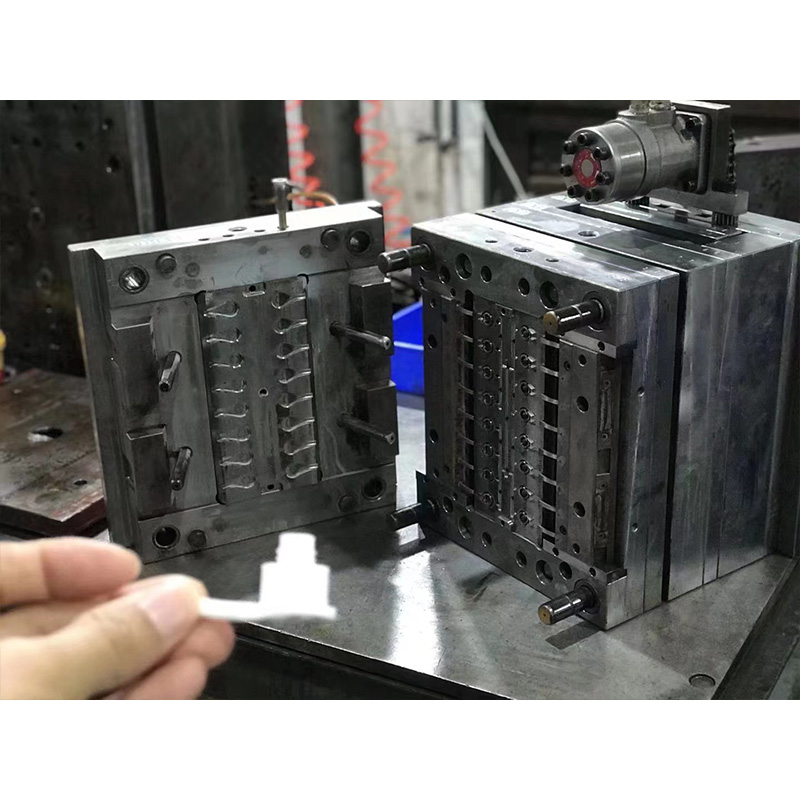

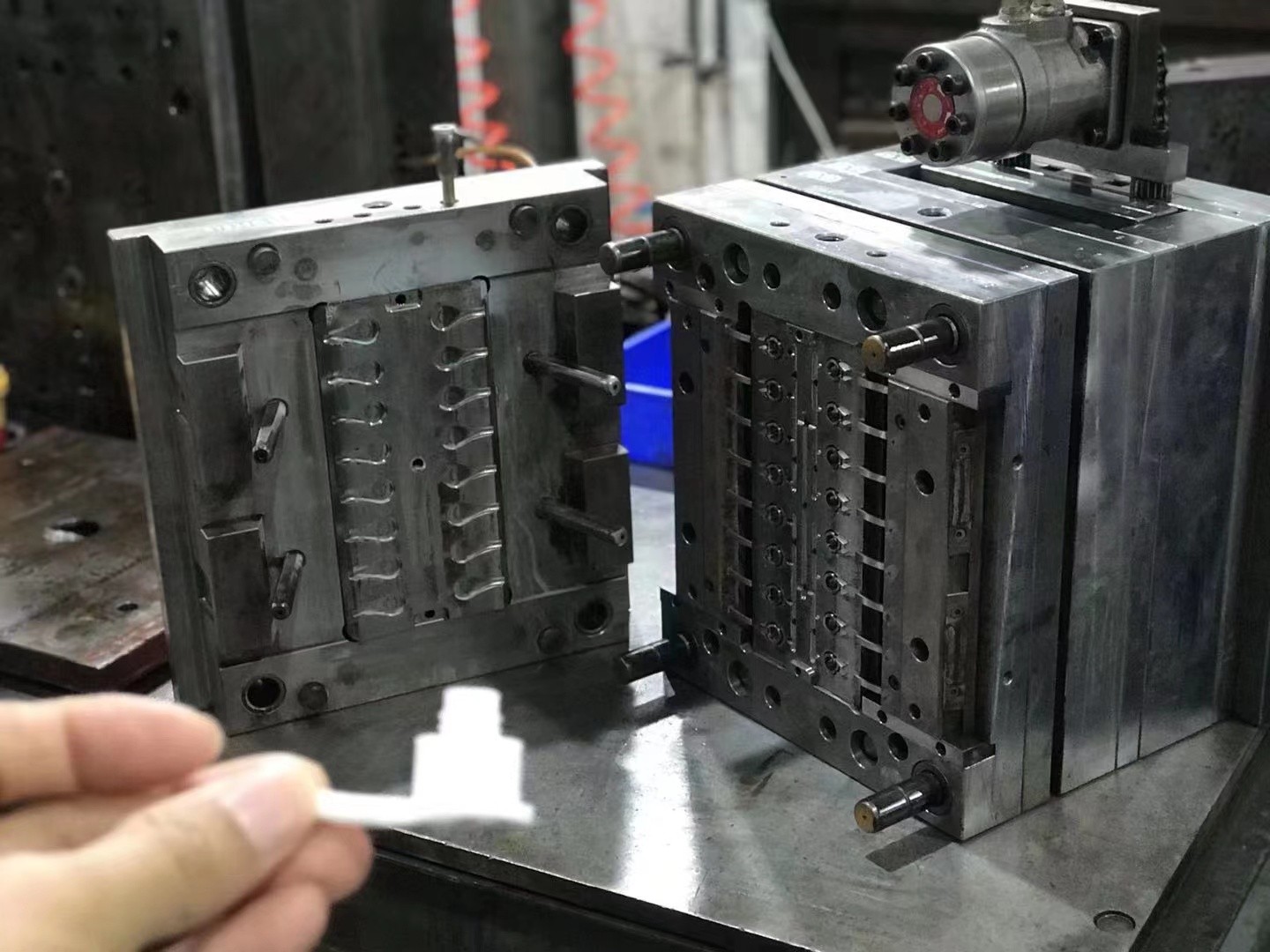

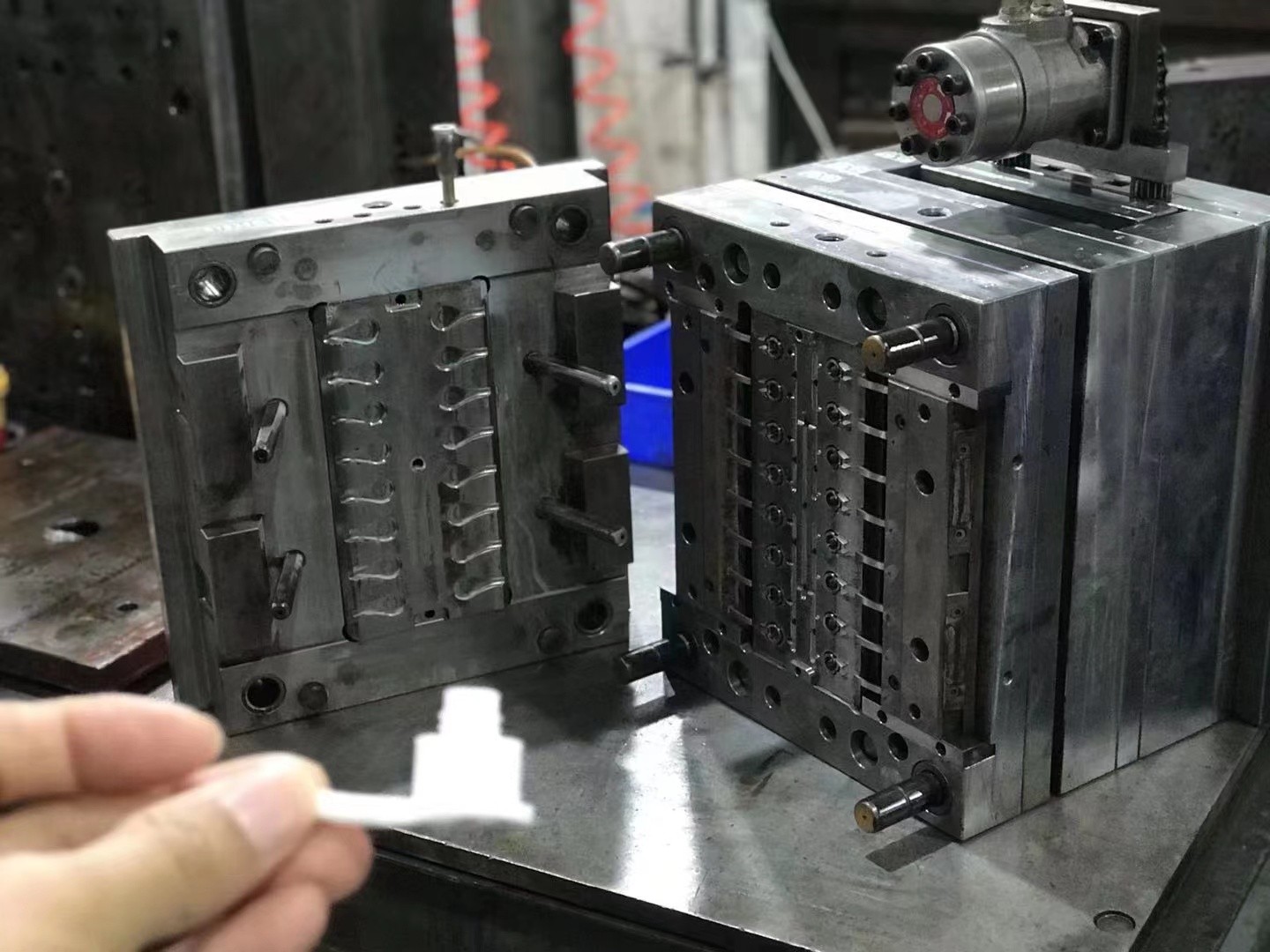

24/410 Lotion Pump Mold Custom And Ready trigger For Delivery

Manufacturing Technique:injection plastic

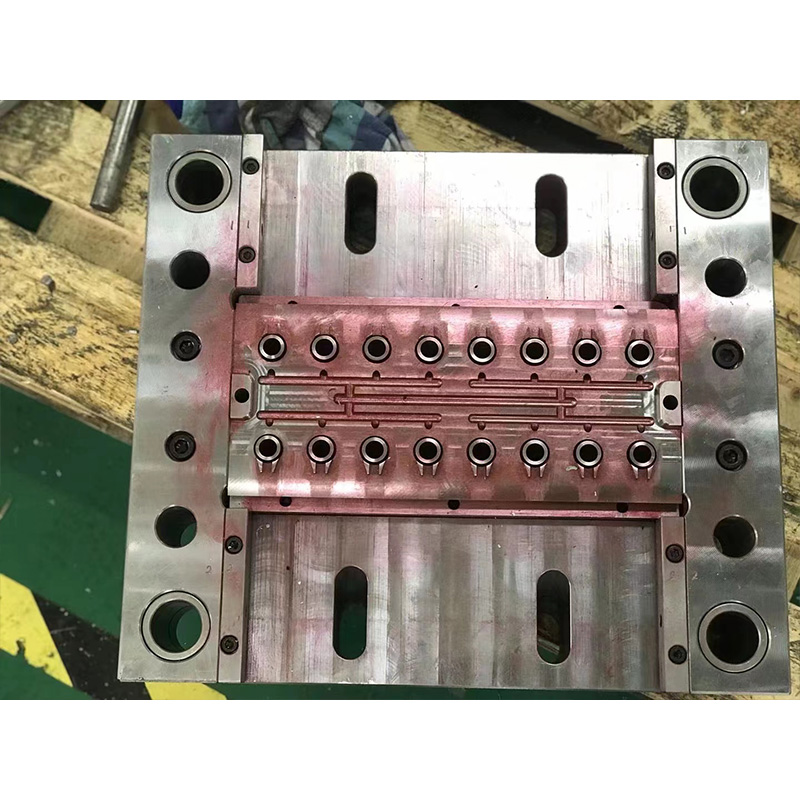

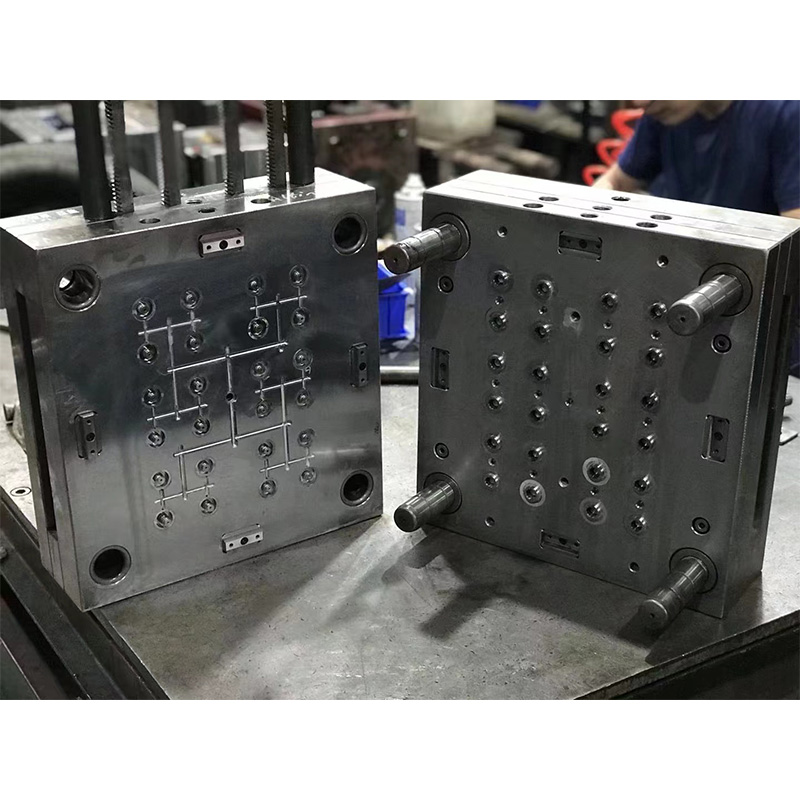

Mould Core:S136

Mould Base :45# steel

Cavity:18

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

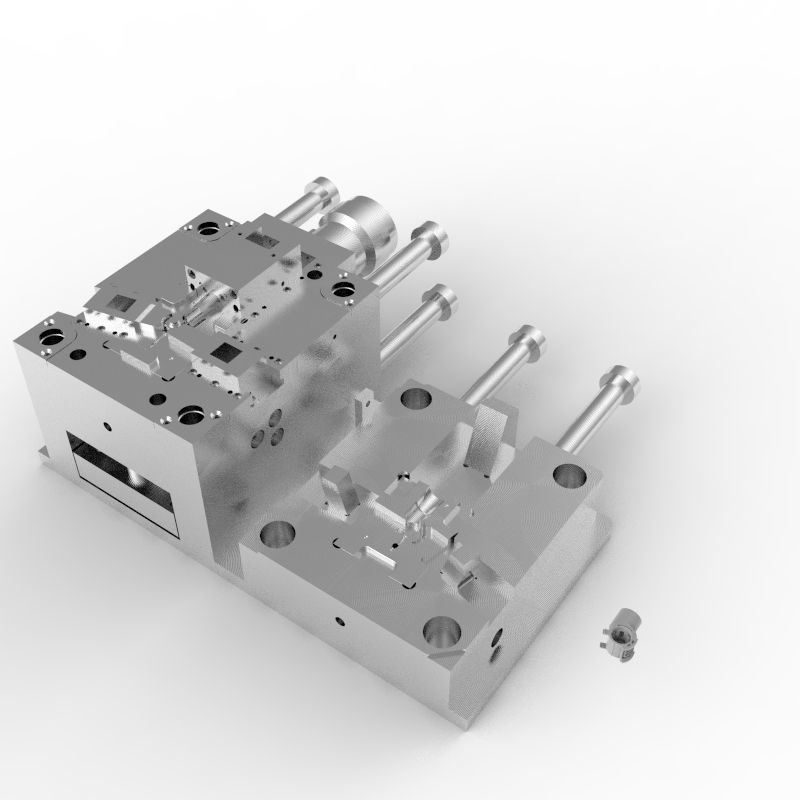

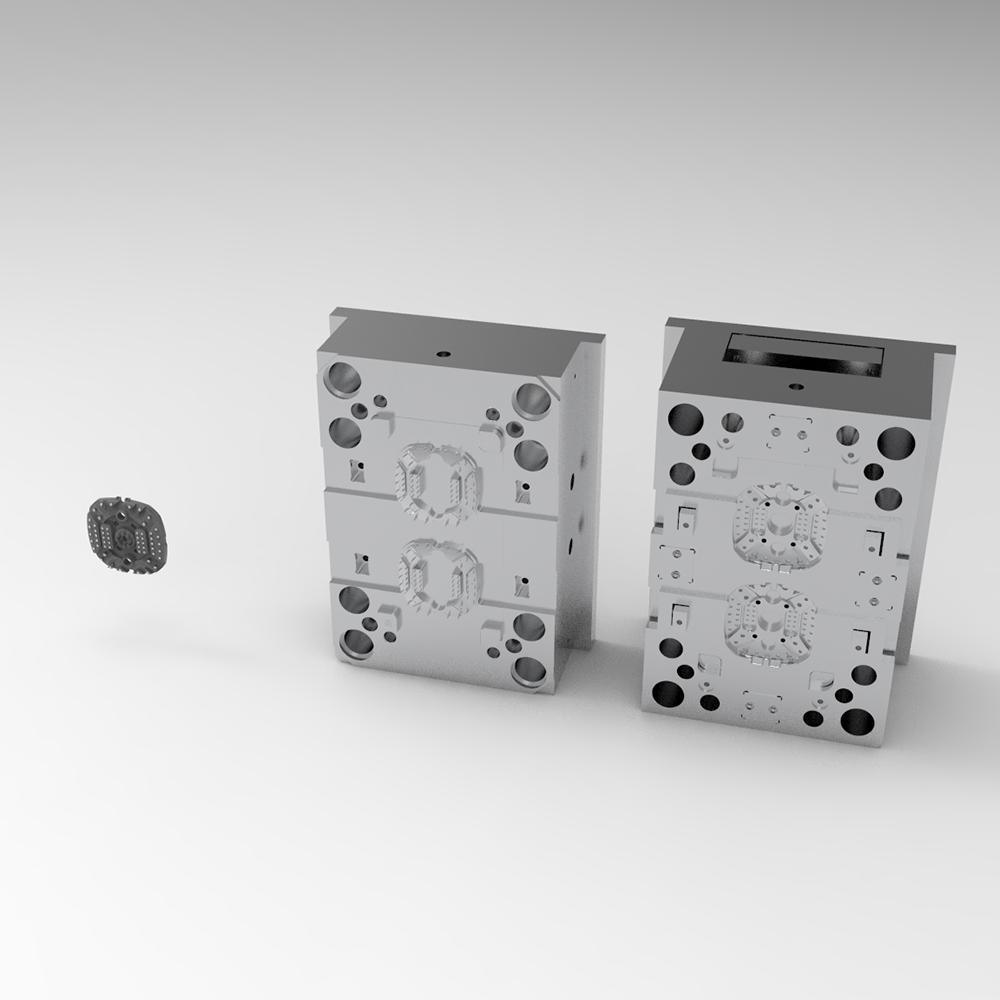

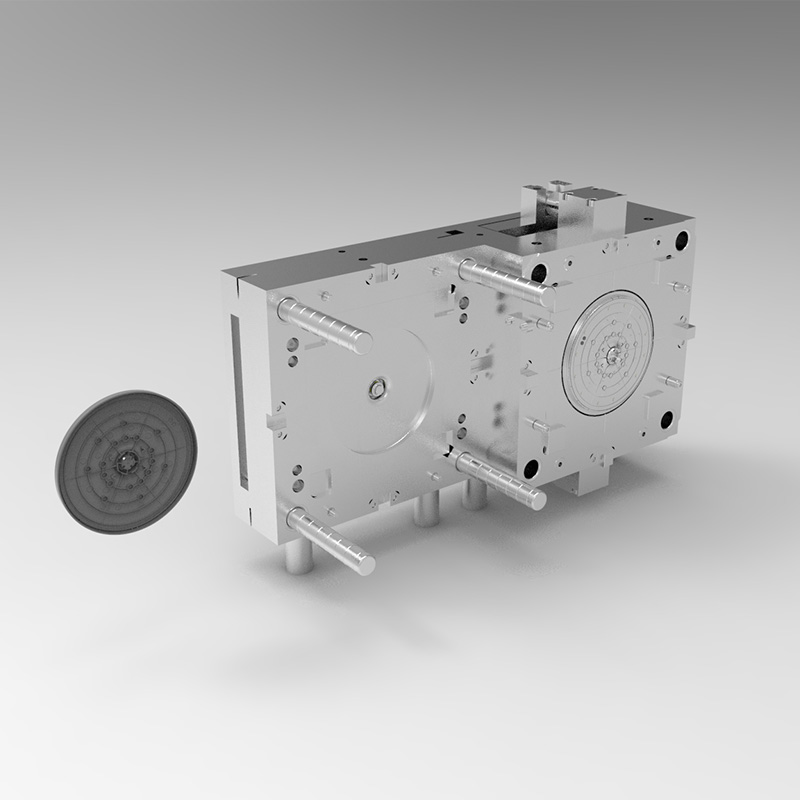

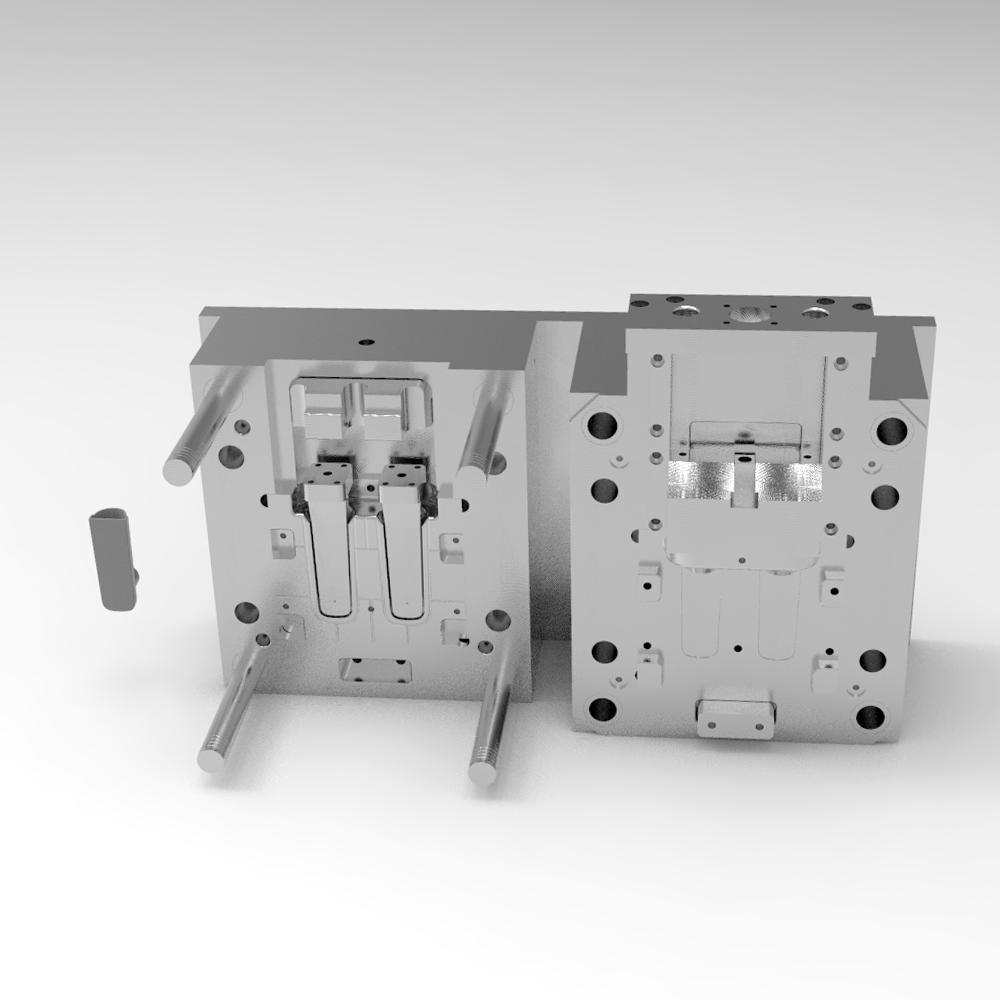

A lotion pump mold is an essential tool for the production of lotion dispensers. It is used to shape and form the lotion pump into its desired shape and size. The mold is usually made of metal and consists of two parts, the main body and the plunger. The main body is the part that holds the liquid, while the plunger is designed to dispense the lotion.

The lotion pump mold is designed to be very precise, so that the lotion pump is able to dispense the exact amount of lotion needed. It is important that the lotion pump mold is made of the highest quality metal, as this will ensure that the lotion pump is made to the right specifications and that it will last for a long time.

Product Specification:

24/410 Lotion Pump Mold Custom And Ready trigger For Delivery

|

factory

| mould name

| mold cavity

| mold core

| mold base

| mold delivery time

| shot(times)

| circle time(second)

|

fengjin

| lotion pump moulds

| 16

| S136

| 45#

| 45days

| 2000000

| 45

|

When manufacturing lotion pumps, the mold is very important. It must be able to withstand the pressures and temperatures of the lotion, as well as the pressures and temperatures of the manufacturing process. The mold must also be able to produce a consistent product, so that the lotion pump works properly.

When selecting the lotion pump mold, it is important to consider the material that the mold is made of. As the lotion pump is designed to be used in various environments, it is important that the mold is made of a material that can withstand the various temperatures and pressures. It is also important to consider the size of the lotion pump, as this will determine the size of the mold needed to produce the lotion pump.

For other plastic injectiom mould welcome to send details.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

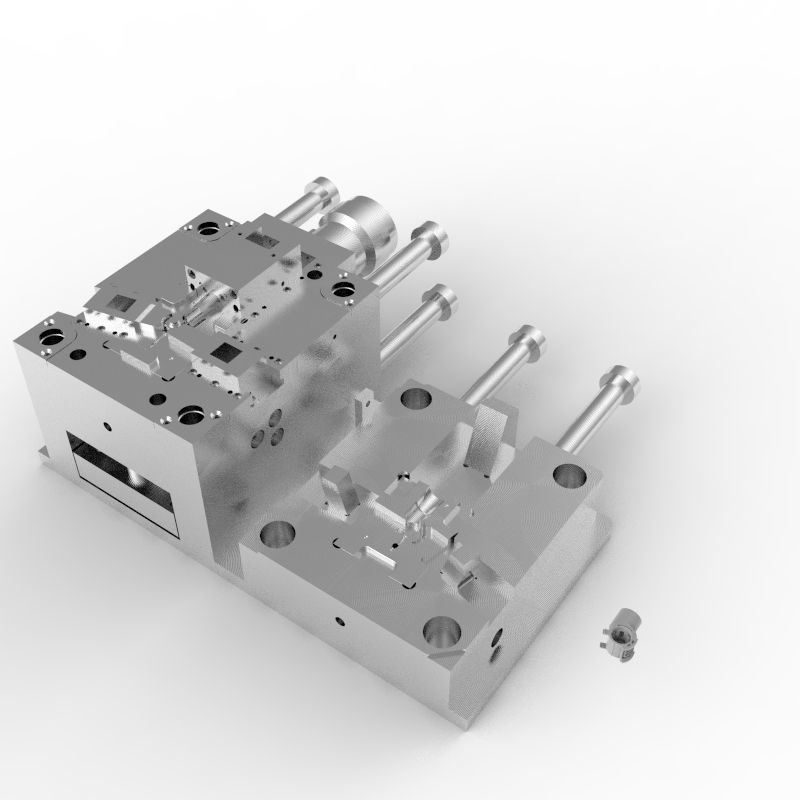

Plastic Injection Mould Manufacturing For Hand Shower

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate